Fermob

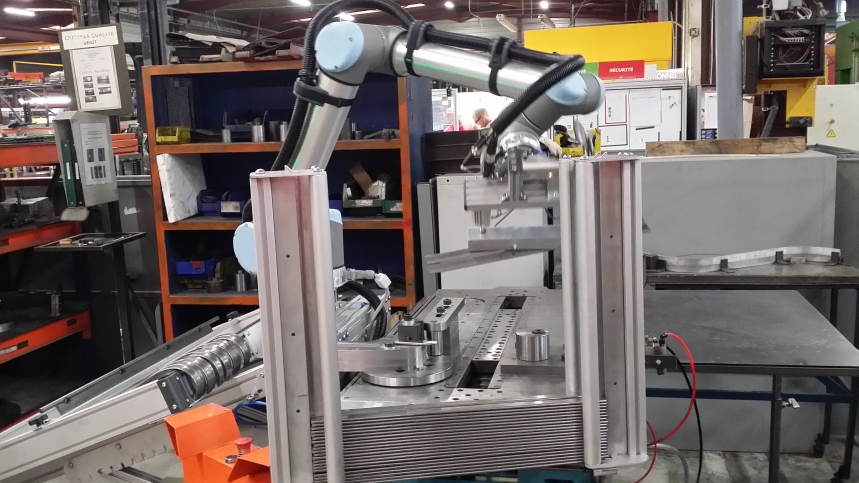

Fermob, an SME that manufactures metal garden furniture, was one of the first companies to use the Arthur tool, created by Cetim to assist SMEs in acquiring their first collaborative robot.

Fermob, an SME that manufactures metal garden furniture, was one of the first companies to use the Arthur tool, created by Cetim to assist SMEs in acquiring their first collaborative robot.

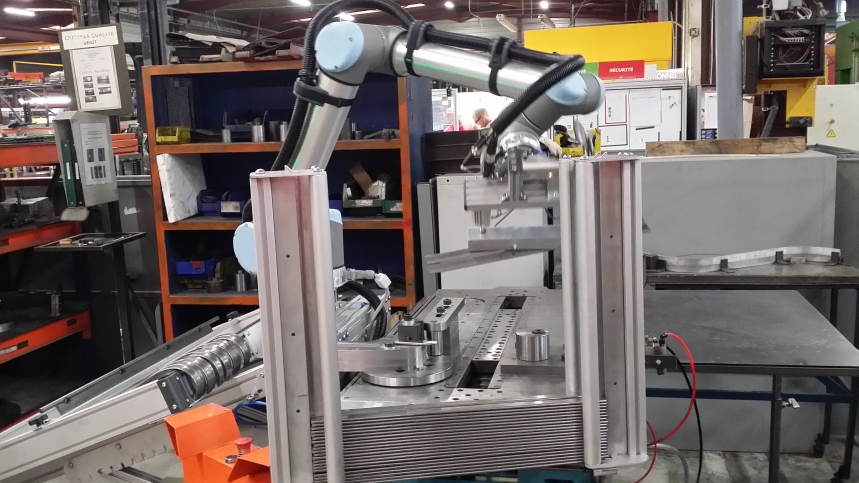

As part of a collaborative project dedicated to the manufacturing of composite parts, Cetim has developed an automated non-destructive testing process for this type of parts.

Together with Cetim, the SME has completed an evaluation of its dyeing process and reduced the investment required for the treatment of its effluents by two thirds. As a result, it can now grow and carry on with its acquisition of production equipment.

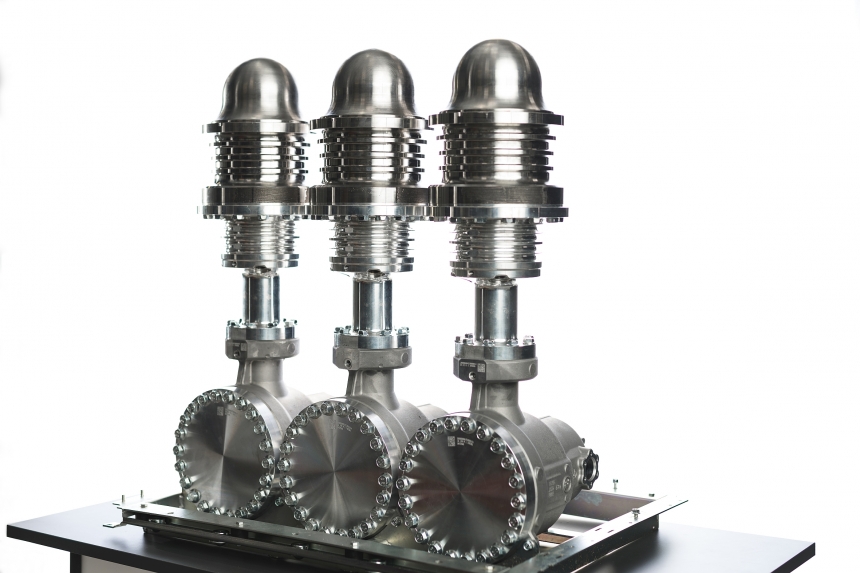

The nuclear plant equipment manufacturer asked Cetim to track its forging process. The goal, within the context of an extensive programme, was to confirm the fitness-for-service of a number of parts installed in the equipment pool.

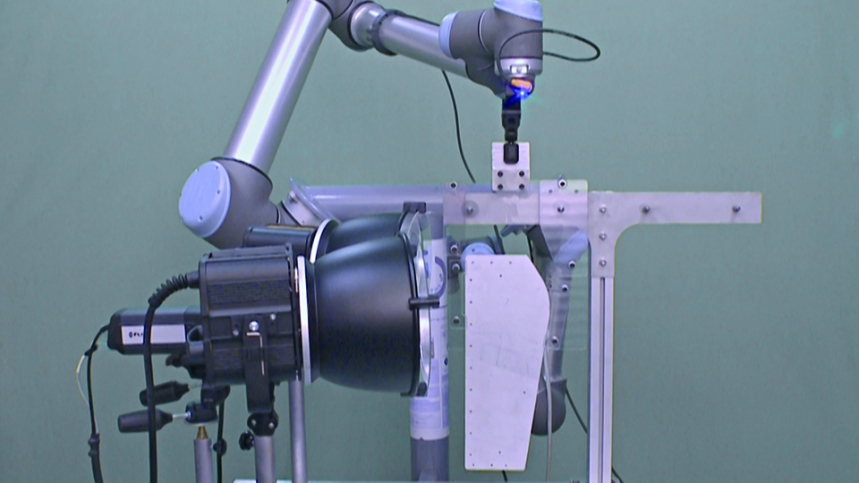

Boostheat’s compressors are exceptionally efficient. Their reliability is strengthened by the appropriate cleanliness of the components used in this innovative technology.

Modernising a small-sized company that has been running on the same business model for thirty years, without questioning, is no small feat. Antoine Pinon has taken up the challenge with his teams, who fully understand the stakes.

In order to position a new grade and challenge its competitors, the specialist manufacturer of specific steels relied on standardised tests optimised by Cetim.

Air Liquide Medical Systems, a subsidiary of Air Liquide Healthcare combined physical tests and acoustic simulations and managed to optimise a medical device which treats sleep-related breathing disorders.

Two vibro-acoustic modelling methods were combined to validate the design of vacuum trains for the New York City subway network.

At La Hague, the french company Orano Projets has revised the design of operculum shuttle components to meet new ASN requirements based on a series of tests and Cetim recommendations.

In conjunction with the 2022 Singapore Airshow, the 10th edition of the Singapore Aerospace Technology and Engineering Conference (SATEC) will be jointly organised by the Republic of Singapore Air Force (RSAF) Air Engineering and Logistic Department (AELD) and the Singapore Institute of Aerospace Engineers (SIAE) on Wednesday, 16 February 2022. The biennial conference provides a …

Continue reading “Cetim experts invite to speak at SATEC 2022”

The 1st edition of the International Metal Additive Manufacturing Symposium at Cetim, Senlis, France. Two days conferences / Six sessions: => Metal AMS program and speakers on: www.metal-ams.com Useful information: Registration fees: 200€HT On Site – 150€HT Online Location: Cetim52 avenue Félix-Louat 60300 Senlis, France Schedules: Wednesday: 9:00 am – 6:15 pm: …

Continue reading “Metal AMS 2022 : International Metal Additive Manufacturing Symposium”

Providing better, faster treatments, adapting to the characteristics of each patient… the medical and pharmaceutical industries face major challenges to enable populations to live longer in good health. Mechanical engineering and Cetim play a decisive role in the constant quest for excellence. Enabling humans to live longer in good health. Such is today’s — and …

Continue reading “Mechanical engineering at the heart of future healthcare”

A comprehensive failure analysis carried out quickly and efficiently on a bridge, enabled French temporary structures specialist Locapal to make the rights decisions without delay. A temporary bridge over a motorway was ready for commissioning when a fractured bolt came to light. As safety is always Locapal’s first priority, the site management team immediately returned …

Continue reading “Locapal’s Testimonial : failure analysis completed in double quick time”

GET ON BOARD THE AEROSPACE ENGINEERING OF THE FUTURE, for a Greener Aviation Industry ! Cetim and Matcor, its Singaporean subsidiary, are pleased to announce their participation to Singapore AirShow, 15/18 February 2022 – The Changi Exhibition Centre, on the GIFAS Booth A-F01. Cetim experts will also lead a conference at SATEC on February the …

Continue reading “Discover our solutions and services for a greener aviation industry”

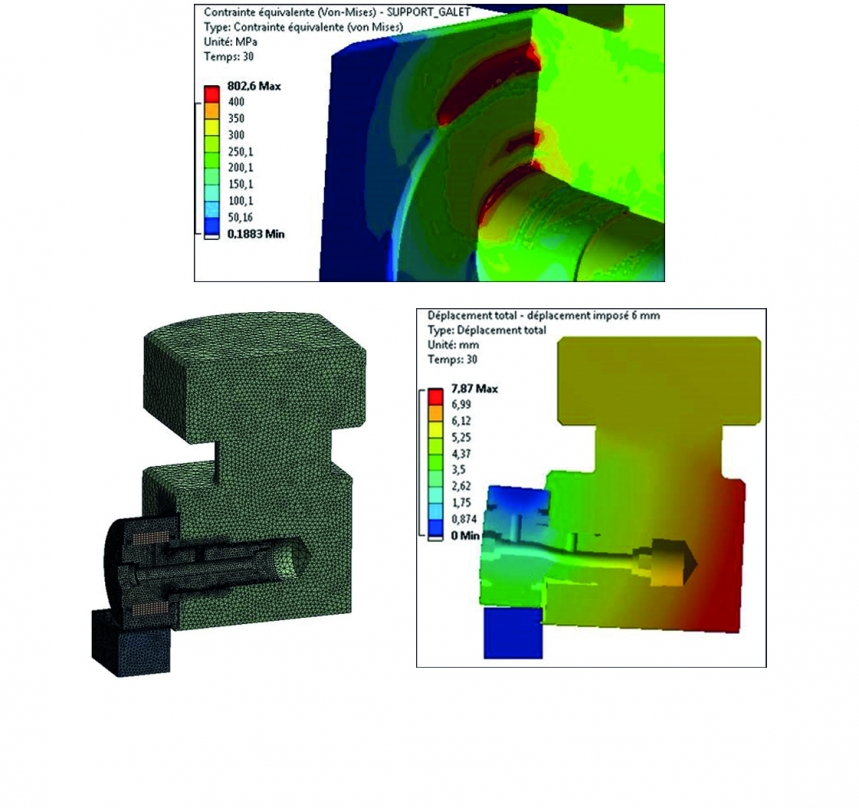

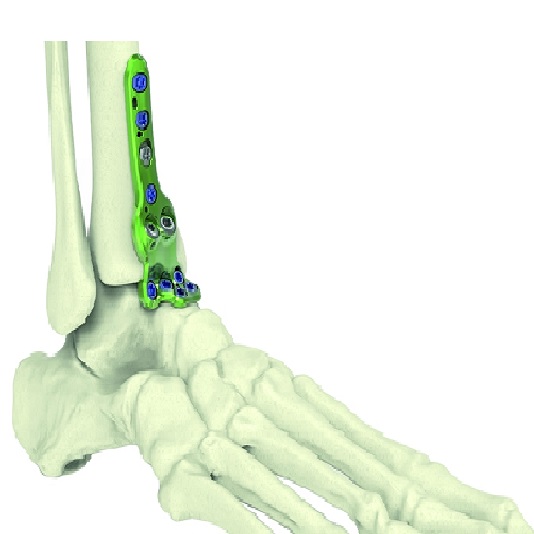

In the world of orthopaedic implants, customised test protocols often need to be developed for complex products. The French industry specialist, Newclip Technics, called on Cetim for this process. Although some orthopaedic implants are covered by standards, when it comes to complex products, manufacturers have to devise and implement customised test protocols that are suited …

Continue reading “Customised test protocols for Newclip Technics implants”

From 17 to 20 May 2022, Cetim will participate in a same booth with the Fédération des Industries Mécaniques at the Global Industrie 2022 exhibition. Global is a referent industrial event in France, with an international dimension, both a showcase for innovation and a platform for exchanges. A complete offer bringing together in one place …

Continue reading “Global Industrie 2022 : The leading exhibition for manufacturers in France”

Complete your design work with our sealing expertise YOUR EXPECTATIONS Energy transition and sustainable development require better containment of some fluids, better leakage control and full compliance with new requirements. As an equipment manufacturer or user, you want to: Design and size an item of equipment or a component so as to…

Dynamic sealing of rotating machinery Test benches to qualify and validate dynamic seals YOUR EXPECTATIONS The green energy transition imposes, inter alia, better control of friction (highly energy consumers) and leaks (pollution). You are a manufacturer of dynamic seals, you want to improve, optimise or check the sealing performance of your seals: Validation…

YOUR EXPECTATIONS Further to failure, damage, deterioration or drop in performance suffered by your thermofluidic system (hydraulic, pneumatic, etc.), you want to: Understand and solve the problem Obtain assistance for the selection of components Verify the conformity of a component or the installation OUR SOLUTIONS We can provide assistance in many fields of application…