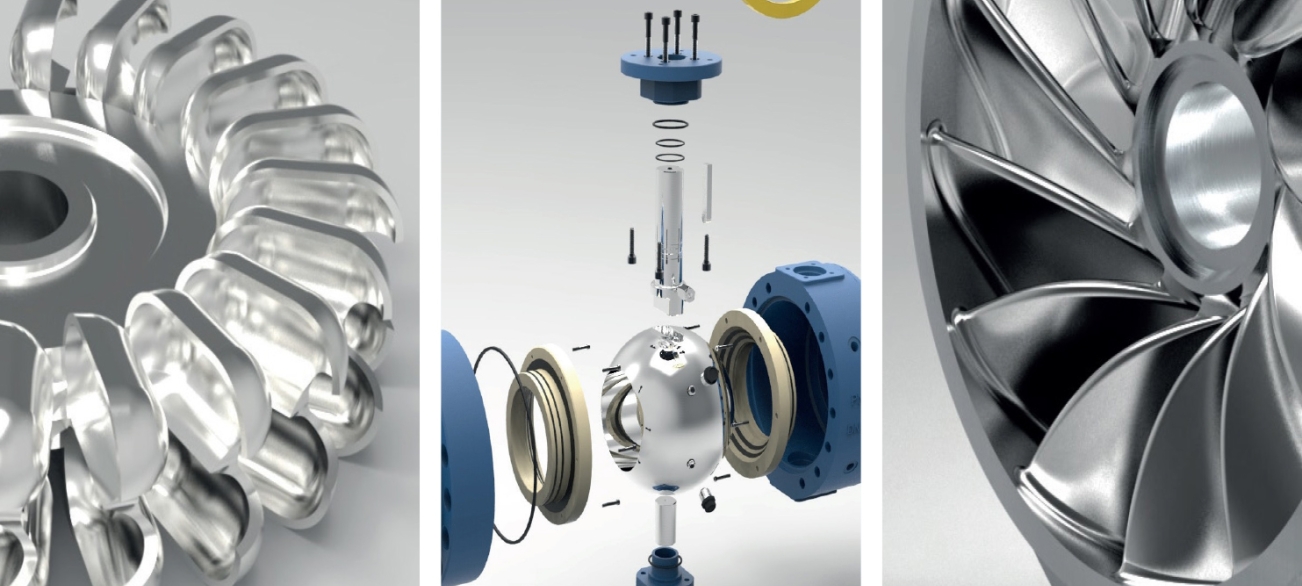

AK Steel’s new NITRONIC® 60 ARMCO® grade presents a strong case: four to five times less cavitation wear, no pitting observed after 192 hours of exposure to salt spray and a seven to eight times higher galling threshold compared with X3CrNiMo 13-4, the steel normally used for applications in the hydropower sector! To demonstrate these advantages to European industrial manufacturers, the American stainless steel specialist adapted to its target.“The properties of the NITRONIC® 60 ARMCO® grade were first determined in our laboratories in the United States. When we began to offer this material grade in France in 2017, our major customers objected to us that the tests used did not comply with the European standards and, therefore, that a comparison with conventional solutions was not possible. We eventually turned to Cetim, based on the advice of one of our customers”, says Christophe Le Roy, Business Development Manager with AK Steel France.

An “improved” galling test

In agreement with the customer, AK Steel selected the tests to be carried out among the standard tests offered by Cetim: galling, cavitation, salt spray resistance, wear resistance, etc. For galling, AK Steel selected a “pin-on-plate” test in accordance with standard ASTM G-98; however, this test was improved by Cetim so as to go further than what the standard requires and obtain more accurate results. “Now we can put forward figures that meet the requirements of the standards in force and are certified by a recognised player in order to prove the advantages of our product for all applications where cavitation phenomena lead to material removal and thus to significant risks of galling: wear parts, compressor shafts, robots in space, cable stay bolts on bridges, etc.”, says Christophe Le Roy.