Fermob

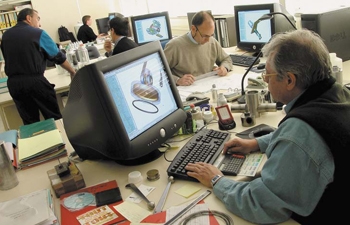

Designing and manufacturing chairs meant to attract customers at the lowest cost: this is the challenge achieved by Fermob, which uses reverse parts engineering based on full-size models made by designers.

Designing and manufacturing chairs meant to attract customers at the lowest cost: this is the challenge achieved by Fermob, which uses reverse parts engineering based on full-size models made by designers.

SMTC’s new bonding process has received the DIN 6701 certification required by the German railway industry – a fine success for a company that generates the majority of its turnover in the rail sector.

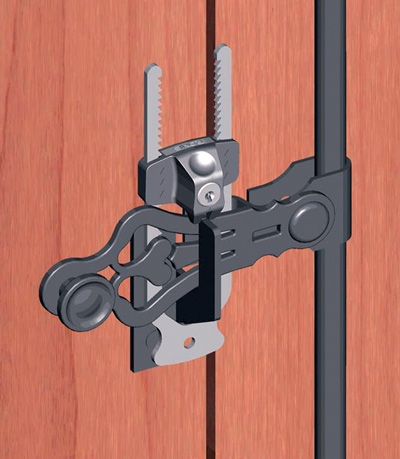

When designing its system for locking shutters from the inside, Ronis followed the NF E 01-005 eco-design standard, a standard that the company shall gradually apply to its entire range of products.

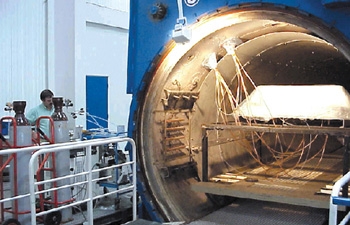

Airbus is optimising the leak tightness of its moulds intended to manufacture large-sized parts – in particular for the future A380 - with contribution from the mechanical industry.

Explore more Cetim’s Aerospace solutions and customer experience

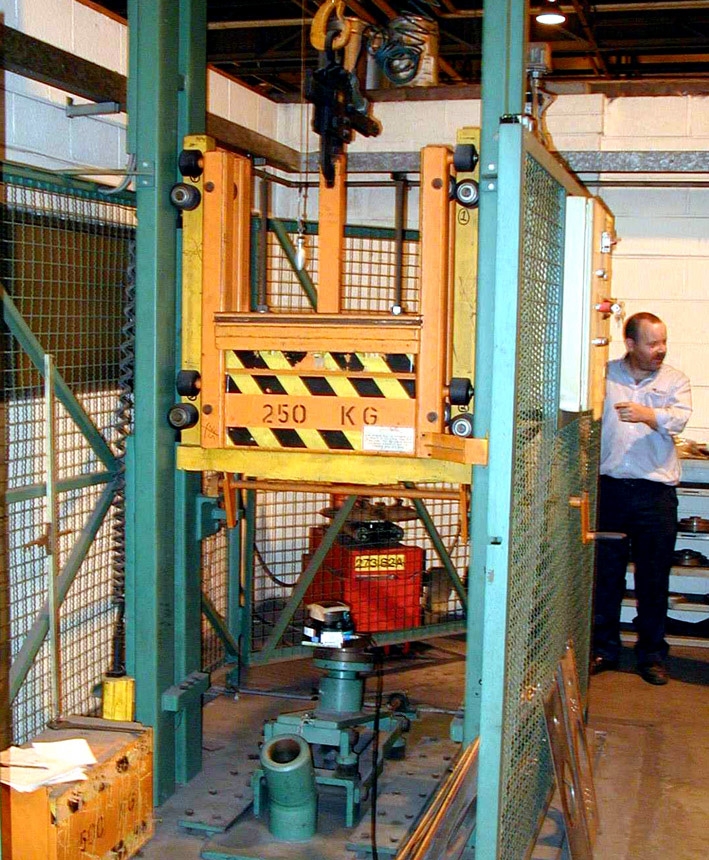

Specialized in the manufacturing of stainless steel clamps, Caillau gets an in-house integration of the design and validation of its components dedicated to the automotive industry. Considering the development of a new connecting clamp for exhaust lines, Cetim has developed a testing bench compatible with the company’s pneumatic facilities.

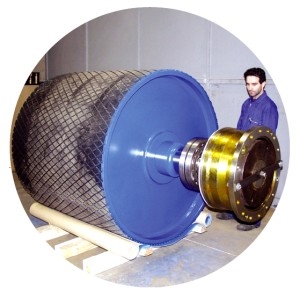

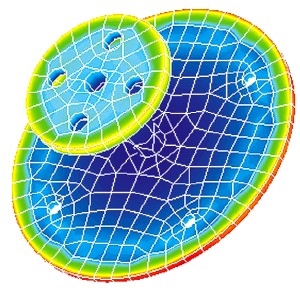

Thanks to a specific development of a finite elements computation software, Mecadrum innovates, optimizes its products and gains new markets.

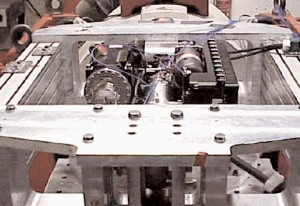

PSA has called on Cetim to determine the cause of the vibration problems with which it was confronted on a test bench, and to find adequate solutions.

Airbus A380’s features lead to an exceptional project and the high safety level required commands to submit its components to rigorous mechanical tests, at levels that were never yet reached.

The simulation of electro-depositions has proven its worth with costs saved on deposited metal, reactivity and guaranteed quality.

Concerned about controlling its activity’s noise-related impact on the environment, Montupet collaborates with Cetim on a regular basis...

Before their launch production, the rims designed by Montupet are validated on test benches in ordor to proof their resistance. Only the telemetry used to find the stress endured during the rotation.

The Cristalleries de Saint-Louis create and produce usual and decorative objects appreciated in the whole world. Here, aesthetic sophistication is only matched by the manufacturing quality. The company seeked for expertise to characterize the adhesives it uses and to define the implementation of bonding processes.

Cetim expedites project management while reducing the risks of poor decisions and cost overruns by providing assistance to project owners.

Superba's top management called on Cetim’s operating safety specialists in order to quickly react to the forecast performance of a competitor machine which stood a chance of challenging the company’s strategy and results. As a result an innovative curling machine, providing a 99.9% availability, was created and became the market leader.

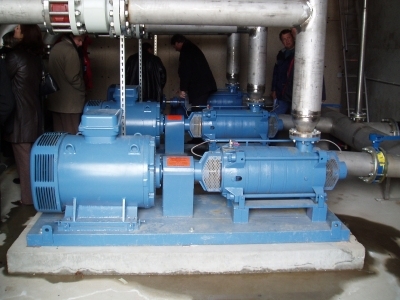

The Syndicat des Eaux de la Semène was confronted with erratic dysfunctions of its new pumping installation, undergoing in particular repetitive variable speed transmissions breakages. It called upon Cetim to highlight nonconformities in order to force the installers to meet their obligations.

Terex Cranes France improved the quality of its stackers by associating reliability analysis, mechanical expertise and the knowledge of materials. This risk management enabled it to improve the performance of its equipment.

Starting from the implementation of a new management system, Tournaire re-examined the whole of its organization which needed solutions fitting to its various activities.

Volvo Bus France chose to have carried out a CID (control by detailed inspection) before homologation of its new natural gas vehicle. A safety guarantee for the customers and the insurance of a better vehicle availability.

Chantiers de l’Atlantique used acoustic emission techniques to check the workings of certain machine equipment on the Queen Mary 2.

Implied in a process of ISO 14001 certification, the managers of EDF Gaz de France Distribution Metz Lorraine decided to carry out a thinking on environmental problems. They particularly wanted to more precisely evaluate the possible risks related to their former activities of storage of electric transformers on a site in Moselle.

“At the beginning, within a strict safety approach, we simply planned to withdraw the soil from old transformers storage areas on one meter depth and to eliminate suspect earth by incineration”, explains Pascal Cauchin-Simon, in charge of estate issues at EDF Gaz de France Distribution Metz Lorraine. This solution would have cost several million euros!

Investing in diagnosis… for cost-effective curative solutions

To ensure the relevance of this approach, the company decided to ask Cetim for a soil diagnosis which would include a historical study of suspect grounds and a study of the surroundings to evaluate their vulnerability. And the results were unexpected!

The study showed that none of the eight investigated sites had any notable contamination according to the current regulation and practises adopted by EDF Gaz de France Distribution Metz Lorraine. Thus, no particular action of rehabilitation was necessary!

A good surprise which also permitted to limit the number of analyses to the first meters in depth when those appeared to be in conformity. A commitment which does not seem so frequent on the profitable market of diagnosis. In this field, “I particularly appreciated Cetim’s transparency and independence”, continues Pascal Cauchin-Simon. A satisfaction which immediately brought results : the company entrusted Cetim with the diagnosis of two other places in 2007.

Cetim’s asset

Cetim has strong skills in all fields regarding soil protection and environment. With no involvment in depollution, its impartiality is a guarantee of reliability and a source of savings for companies.

Our customer:

Company name: EDF Gaz de France Distribution

Activity: EDF Gaz de France Distribution operates both for EDF and Gaz de France. It exploits and ensures the network’s maintenance, build and maintain the installation for electricity supply, and manages the metering actions.