Aerospace Market's Big Challenges

In a fast moving aerospace market, Cetim is your i4.0 engineering partner to succeed in your transformation to Net Zero Carbon and meet your production ramp-up challenge

Reduce your emissions

Optimize your manufacturing & operating costs

Succeed your production ramp up

Accelerate your 4.0 technologies integration

Design of a Krueger flap in TP composite

Learn more on the design of a Krueger flap in TP composite with Cetim’s SPIDE TP process, within the framework of the European R&D project SWING, part of the european Clean Sky2 program, for more efficient wings and more efficient aircraft.

- In-situ consolidation with the award wining SPIDE TP fully automated process

- Repeatability and reliability of the process

- Reduction of production costs

- Optimised product quality with improved impact resistance

- Recyclability on waste during production or at end of life.

Our Solutions

Delivering a complete suite of solutions, trusted by +850 aerospace customers in all the supply chain

New Generation Aircraft

Design & redesign commercial & freight aircrafts more customized, lighter and integrating more & more recycled parts

How?

- Mastery of new composite materials, innovative metallic materials & multi-materials assembly

- Materials Testing:

- Metallic, polymer and composites tests : +40 Nadcap accreditations for non metallic material testing

- Engineering testing:

- Development of customized multi-physical tests & benches : high speed/high power

- Simulation-test correlation

- Smart Testing (IIoT, test data exploitation)

- 3D Scanning

- Additive manufacturing

- “Reach” compliance

- Recycled materials validation (performance, durability)

- LCA, eco-design

- CETINNOV, a disruptive innovation methodology to enable companies to design or redesign their products on an entirely new basis

New alternative propulsion systems

Towards Net Zero Carbon 2050

How?

- Sustainable Air Fuels

- Materials compatibility, sealing…

- Hydrogen tank :

- Design and validation

- Disover our HyMEET project (Hydrogen Material and Equipment Engineering and Tesing Center), which aims to guarantee industry the technological mastery required for hydrogen in its gaseous ad liquid state.

- Electrification:

- Propulsion systems and components validation: electric motor, rotor, stator, gearbox, reducer, power electronics…

- Noise reduction

Factory and Hangar of the future

Exploit the Industry 4.0 technologies to improve Industrial efficiency - Ensure reliability, availability & reduce operating costs

How?

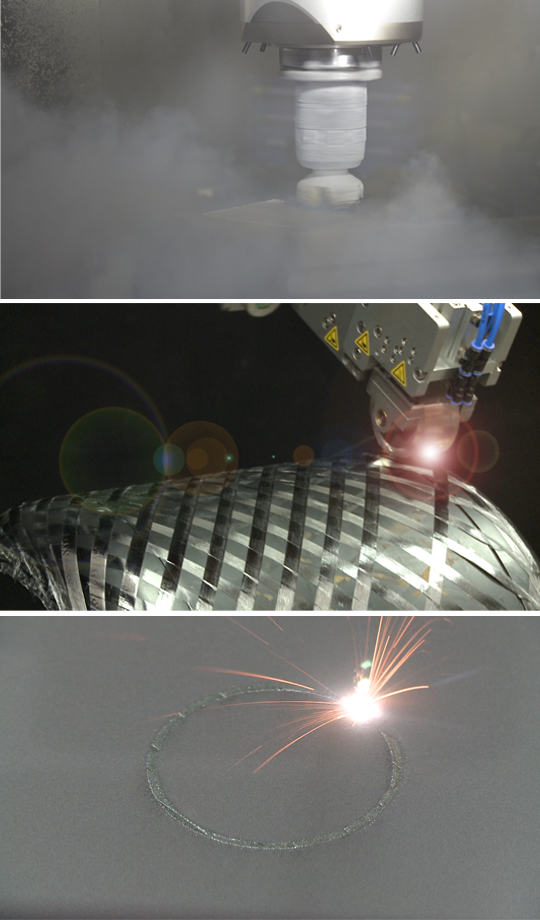

Innovative manufacturing processes industrialization and optimization

- Metal additive manufacturing

- Material / process combination choice

- Design engineering

- Proof of concept

- Post treatments (TTh, TS, finitions)

- Controls, qualification and caracterization testing

- Innovative thermoplastic composite processes (QSP…)

- Machining

- Cryogenic assistance,

- Assisted vibratory drilling,

- Self adaptative machining (Usitronic),

- Efficient assemblies

- Automation, Robotics : machining, finish, assembly, NDT…

- Connected tools

IIoT and predictive maintenance

Non destructive testing (NDT) and 3D scanning

Failure analysis, as a support to master the risks

Consulting and Cetim Academy training courses

Support the Industry 4.0 transformation and the development of associated industrial skills

How?

- +500 Cetim Academy® training programs to develop talents

- Strategic transformation, Manufacturing optimization:

- Strategic consulting

- Technological expertise

- Operational performance

- Data management

- New business model development,

- Diversification

- …

- Failure analysis and integrity