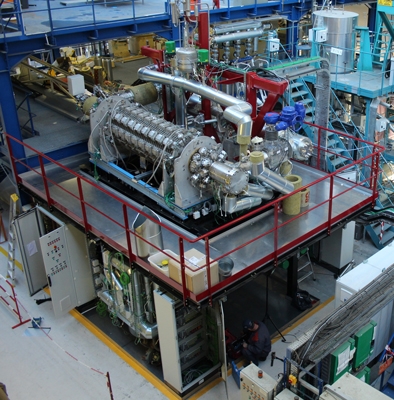

Technidrill

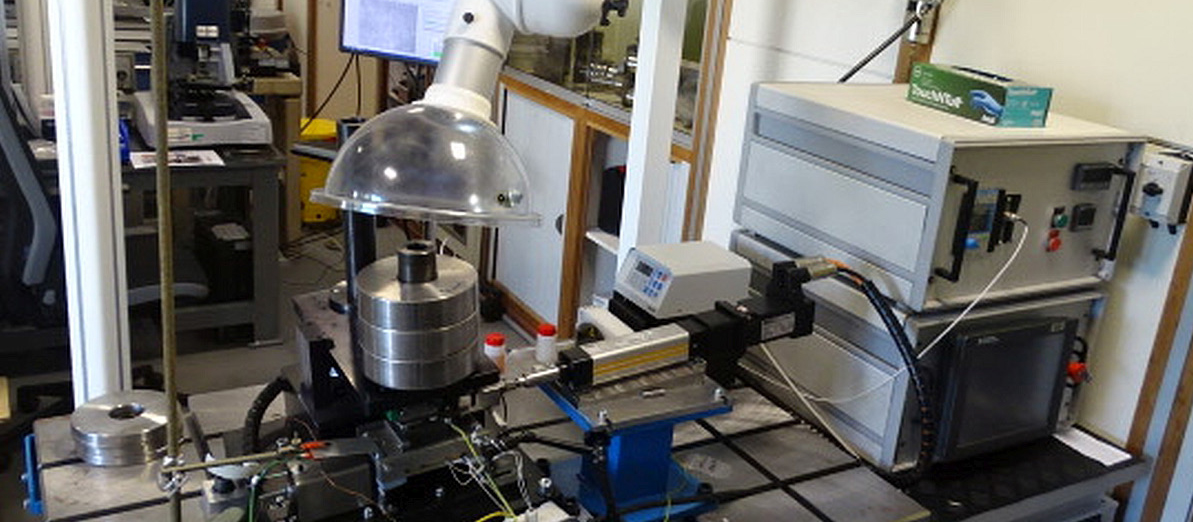

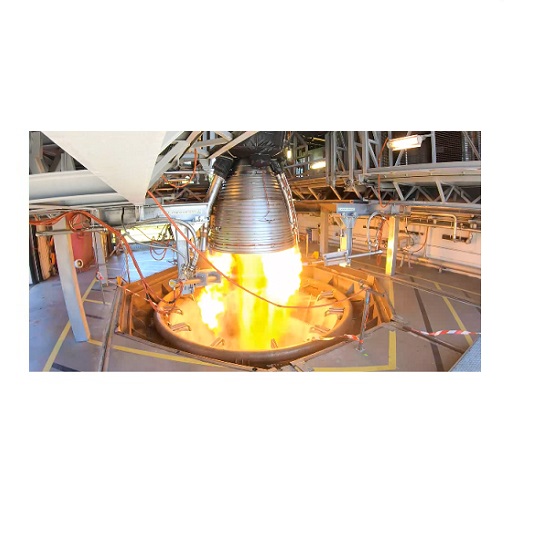

After a study of its coring rods, Technidrill can boast a shot blasting mechanical hardening solution for drilling in abrasive ores, to prevent the appearance of cracks in its components.

Explore more Cetim’s Oil & gas solutions and customer experience