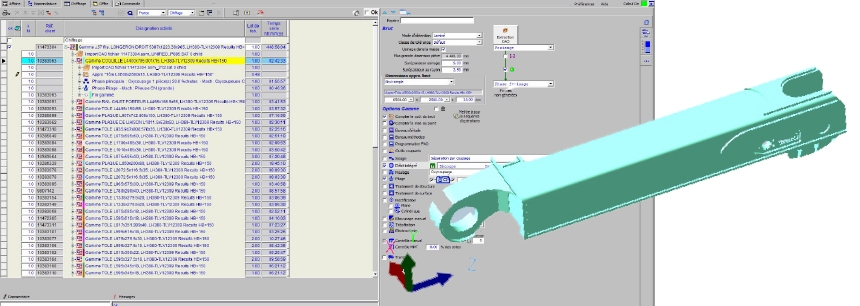

Liebherr-Mining Equip-ment, based in Colmar (Haut-Rhin, France), manufactures hydraulic shovels and trucks: complex assemblies combining machined parts and sheet metal entrusted to its sub-contractors. "We needed sophisticated software able to simulate/calculate manufacturing costs in order to question the rates suggested by our suppliers on an equal footing", explained Frédéric Kieffer, a corporate cost optimisation engineer. In 2016, the industrial firm opted for Cetim's TechniQuote. In practice, the user drags and drops a CAD file in the software window. TechniQuote will automatically detect the types of parts (geometry and associated technical data) and can then be used to configure the geometry of weld seams. The software then estimates manufacturing lead times and cost for each part and the entire assembly. This quote is supported by a full-scale "virtual plant", i.e. a massive database for materials and machines. Liebherr- Mining Equipment uses this software to produce quotes for assemblies ranging from 30 to 80 parts, and sometimes more.

Cost reduction

"The cost of each part is analytically broken down in TechniQuote, considering pro-cedures, phases, shapes and operations in order to identify which are the most costly, and above all, why", explained Cetim's Maryse Provost. TechniQuote can also be used to compare the prices of the different manufacturing alternatives. The Liebherr- Mining Equipment engineering team uses both of these functions to boost the design of its parts. "We start with a "top 5" for the most expensive parts, and discuss how we could reduce the inherent costs in-house, e.g. by modifying the design, the material used, or the associated quality requirements, and then we advise our design team", detailed Frédéric Kieffer.

TechniQuote has been up-graded since its launch, with the addition of a sheet metal module. Thanks to a pilot version proposed to various stakeholders, including Liebherr, the module has been adapted to field requirements and part types are automatically identified by the software.