Expertise in leakage measurement

Our whole expertise to help you master your fluids

Our whole expertise to help you master your fluids

Real-time monitoring for better productivity and more reliable facilities

Effective test benches to optimize your pumping equipment

A unique expertise in the field of fluids

Calculation and simulation to improve the performance and robustness of your products, reduce the time-to-market and maximize equipment availability.

Characterise the physical-chemical properties of a metallic material

Choose the tool fitting precisely to your production

Choose the best fitted materials or surface treatments for machine components in order to improve your equipment’s order-fill ratio

High-precision 3D measurement on every type of materials

On-site measurement for large parts

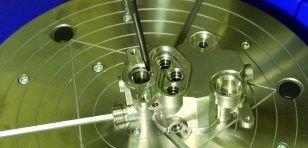

Get a high-precision 3D-view of your circular parts (shape defects, cylindricity, circular roughness)

Outsource your measurement tool calibration and control

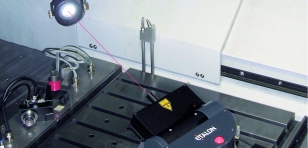

The Laser-Tracer : a technology intended to improve machine tool and 3-dimensional measuring machine control

Energy dispersive phase analysis

Management and calibration of your measuring instruments pool

The best expert recommendations to help you improve your metrology function

A local self-service offer in our metrology laboratories