The new machine acquired by Cetim will break records in tape laying speed for the production of composite tanks. Its core area of focus is the manufacture of hydrogen tanks for clean mobility.

.

Tape winding is rapidly becoming a viable solution for the production of hydrogen tanks with HySPIDE TP! The new machine acquired by Cetim, the Technical Centre of Mechanical Industry, offers improved performance, making it possible to produce this type of part with thermoplastic composites, at costs in line with the industry.

As part of the drive to reduce the carbon footprint of mobility solutions, the development of the hydrogen sector requires the design, manufacture and certification of new high-performance and efficient mobile storage solutions that meet the needs of sector players in terms of weight reduction, technical features, impact resistance, durability and recyclability, while, at the same time, optimising manufacturing costs.

10 times quicker than before!

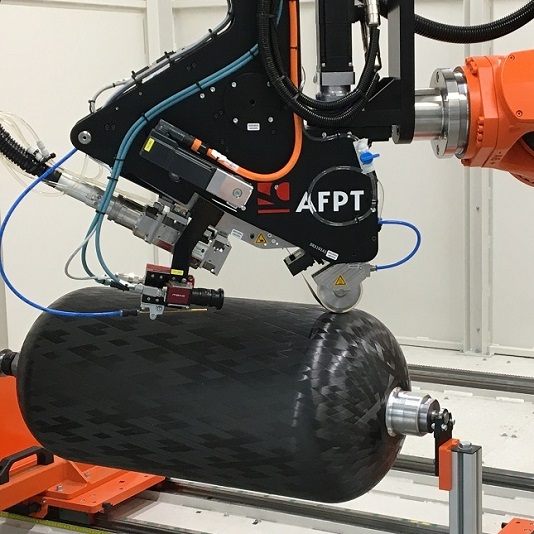

Cetim aims to demonstrate the industrial benefits of laser-assisted tape winding technology with in-situ consolidation through this new robotised cell designed to manufacture thermoplastic (TP) parts (in real time, with no other steps required). Cetim has already shown the technical feasibility of the tape winding process to manufacture hydrogen tanks. The key advantage of the machine is a new head developed by the German company AFPT which, with also an additional axis, increases the tape laying speed by 10 compared with SPIDE TP®, the previous generation of machines already installed and optimised by Cetim and which won a JEC AWARD in February 2023 in the “aerospace process” category.

The tape laying speed will be significantly increased in the cylindrical area as well as in the “domes” of the tanks – the hemispherical parts at each end. It can reach 100 m/min on the cylindrical parts and 15 m/min in the domes. The machine can also lay 40 mm wide tapes, compared with 6 mm previously. In addition, the cell has an external tape supply unit that can accommodate winding reels of 8 km of wire, the maximum production capacity offered by tape suppliers.

This state-of-the-art machine, which focuses on the production of tanks for the mobility sector, together with the centre’s full expertise in materials-product-process, “should make it possible to remove barriers to industrial production and achieve optimised manufacturing costs“, stated Clément Callens, head of Cetim’s Polymers and Composites division. The equipment will be installed in July 2023.

To learn more:

- visit us at the International Paris Air Show on the GIFAS Booth C140 Hall 2B

- watch our video on our HyMEET program

- contact our experts