Discover the results of the latest FactoryLab projet in video: a non-destructive testing tool to fully detect and identify pollutants on the surfaces of interest! A project carried out in collaboration with Cetim, CEA-List, R&D Vision, Naval Group and Stellantis.

The FactoryLab Consortium is essentially a “project hotel” run by the CEA and major French groups. Its aim is to develop operational solutions that meet real needs, and in so doing help to boost the competitiveness of French industry. This platform is a new approach to collaborative, pragmatic innovation, focusing on short‑term projects that can be quickly manufactured at industrial scale. “Grease” is one such project.

“With this project, we wanted to demonstrate the ability to non-destructively detect and quantify the presence of pollutants in several use cases”, explains Guillaume Pors, Project Manager “Grease” at Cetim. As a matter of fact, in many operations such as bonding or welding, particularly in complex environments, assembled parts must be free from dirt or deposits. Before now, inspections were carried out by sampling or when the cleaning protocol was implemented. New methods were therefore needed to achieve 100% testing.

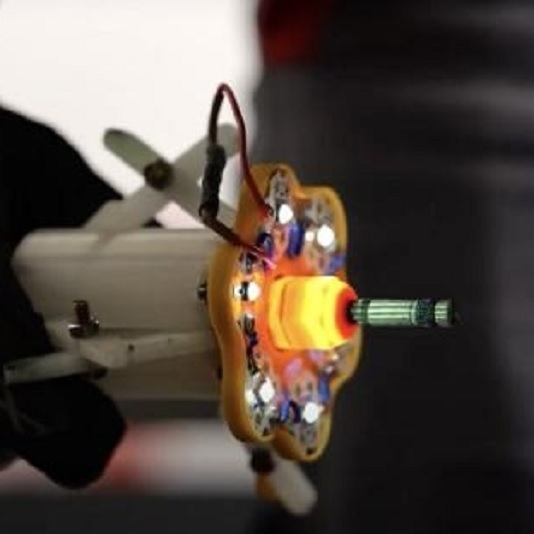

Cetim and its partner R&D Vision decided on two technologies, infrared and ultraviolet, which they tested on several use cases, from the flat, shiny surface to be bonded, through to the internal inspection of tubes.

These various tests highlighted the ability of the two technologies to identify pollutants on surfaces, as well as the differences in the costs related to the equipment and the detection performance. As a result of this work on a range of different applications, the potential for implementation in a variety of environments has also been assessed.

“Grease has helped to validate the principle of vision inspection as a new inspection method for cleaning processes. It will now have to be implemented on a case-by-case basis, depending on integration constraints”, points out Philippe Barate, System Architect at R&D Vision. The process is already underway: “specifications have been drawn up so that a portable testing device can be supplied to all Naval Group sites”, discloses Christian Le Gac, R&D Manager at Naval Group.

Learn more on our services and solutions in control and measurement