Cetim offers manufacturers the use of its equipment and expertise for scanning, reverse engineering and the creation of added value based on the generated digital models. In this article, read an interview with our experts on the broad needs of manufacturers in scanning in all aeras, and the Centre’s strengths in meeting them.

.

3D scanning has become a must in many industrial and non-industrial sectors. Cetim has developed a comprehensive range of solutions around these technologies to meet the wide-ranging needs of manufacturers.

Solutions for differing needs

“Manufacturers have very broad and diverse needs for scanning in all areas”, explained Vincent Barbier, Head of Metrology at Cetim. Design offices use scanning to rebuild and redesign parts. In production departments, these techniques are used to scan a production chain in order to simulate its operation or to build an extension. The technology can also be used to scan a portion of a plant to anticipate the installation of new equipment. In the aerospace sector for example, 3D models of “as built” and not “as designed” equipment may be needed to carry out maintenance work. And the list goes on. In these areas, “Cetim can draw on extensive experience. We have scanned plants for major players in the agrifood and pharmaceutical industries. In the Oil&Gas sector, we have assisted in reverse engineering work for major instructing parties. In the aerospace sector, Universal Hydrogen asked us to scan an ATR 72 for its retrofit to incorporate a hydrogen-powered motor (read our Application article on page 8). We have previously scanned hull moulds for the luxury yacht sector”, pointed out Lionel Lagrèze, tasked with promoting the Cetim scanning solutions.

Equipment and expertise

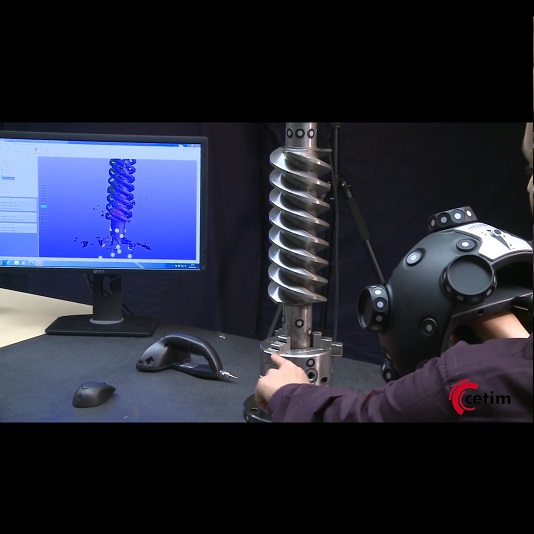

The major advantage of Cetim is that “We have the capability to scan both large and small objects, from a few hundred meters down to a micrometre”, pointed out Vincent Barbier. To this end, Cetim can leverage on an especially broad range of portable Handyscan and Metrascan scanners, structured light optical scanners, in addition to long-range scanners installed on tripods or embedded on drones.

The data generated by all this mobile acquisition equipment is then processed and transformed into analysable files: scatter diagrams, metrological data, 3D models in CAD formats, STL type files for additive manufacturing. “In addition to these files, we can also offer virtual reality or augmented reality media”, disclosed Vincent Barbier. For example, Cetim’s teams have completely scanned the workshops at Cetim’s facility in Cluses, in order to carry out a virtual visit of the premises. “We can pair the scans with information provided by a thermal imagining camera to identify the hot areas and combine it with information such as the overall equipment efficiency (OEE) or technical sheets as well as create dynamic 3D models used to improve processes, simulate flows in a workshop for the purposes of industrial reorganisation”, added Vincent Barbier.

Fast and mobile

A further key advantage of the centre is its expertise: “We operate across the entire scanning value chain and we have engineering expertise, metrology expertise and knowledge of mechanical engineering trades”, boasted Vincent Barbier. Furthermore, Cetim actively carries out R&D in this field. 3D scanning is one of its main cross-functional thematic projects conducted with manufacturers and which address, among other things, the concerns of robotising scanning processes as well as the aspects of reverse engineering: process, design, innovation, eco-design and failure analysis.

Lear more:

- Discover our Metrology & 3D Scanning Laboratory on our youtube chanel

(activate english subtitles within the youtube settings) - Learn in video how Cetim scans an ATR airplane to convert it to Hydrogen

- Contact our expert to learn more on our 3D Scanning solutions and services