As the International Paris Air Show prepares to open its doors, Cetim has just acquired a new scanner whose technical characteristics, combined with the multidisciplinary expertise of its engineers and technicians, are particularly well suited to the challenges of operational efficiency, ramp-up and safety in the aerospace industry. In addition, this new equipment expands Cetim’s services and R&D capabilities in the field of non-destructive testing, enabling the exploration of new materials and concepts.

A scanner for large parts

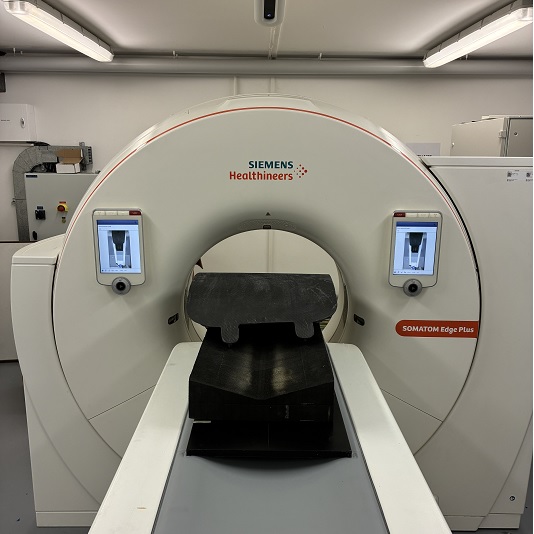

Designed by Siemens Healthineers France, the Somatom Edge Plus was initially intended for the demanding requirements of the medical sector. It features a 100 kW generator and a 78 cm tunnel opening for a scan length of 2 meters. This enables it to scan parts weighing up to 220 kg and up to 3 meters long. These features enable it to inspect complex composite parts in development, such as hydrogen tanks, FAI (First Article Inspection, a crucial step in quality control), sampling, and series production. It is capable of detecting defects that are difficult to spot by other means, such as porosity, delamination, dry resin areas, and macro fiber orientation. It is also particularly valuable in failure analysis. Among the many other advantages offered by this equipment are a reduction in acquisition time by a factor of ten, and an improved resolution for more detailed analysis.

This equipment strengthens Cetim’s tomography capabilities and expertise. To date, seven employees, some of whom are FrANDTB N2 and N3 certified, and seven analysis licenses are dedicated to this equipment, to which should be added other complementary areas of expertise in metallic materials and surfaces, fatigue and performance characterization, etc.

Benefits for the aerospace industry

With this new equipment, players in the aerospace industry can now anticipate maintenance needs on large parts before a problem arises, reducing downtime and improving aircraft reliability. Faster and more accurate inspections reduce the time needed to check each component and increase the overall efficiency of maintenance operations. Finally, it also helps to ensure compliance with the strict safety standards imposed by aerospace authorities.

Cetim will exhibit at the International Paris Air Show from June 16 to 19, at the GIFAS Pavillon, Hall 2B, stand C158 – S2.