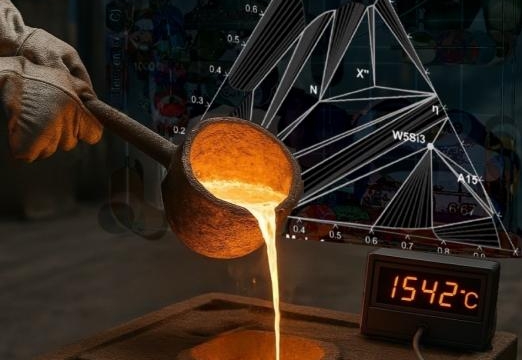

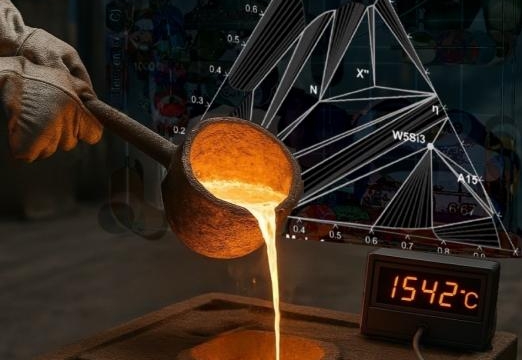

Master your forging and casting processes thanks to comprehensive metallurgical expertise, from digital to experimental.

Metallurgical engineering in foundry and forging

Your expectations

You are a foundry plant (SME, mid-size company), processor, raw materials company, recycler or contractor with integrated production sites, and you want to:

- Develop or characterise new grades of ferrous or non-ferrous alloys

- Resolve manufacturing issues related to recycling, the substitution of alloying elements or changes to your material supply

- Control your metallurgical process (melting, refining, solidification, heat treatment, etc.) throughout all stages of production

Our solutions

Our experts support you in meeting your technical specifications for all types of metallurgy (cast iron, steel, aluminium, etc.) in line with your process:

- Audit of your casting and forging processes

- Bibliography / State of the art

- Assistance and advice for adapting your metallurgy

- Digital approach to development (Thermo-Calc) to validate new candidate grades. Generation of material databases for the simulation of foundry and forging processes

- Semi-industrial scale experimentation (test pieces, demonstrators, etc.) from development to heat treatment

- Experimental characterisation of alloys (mechanical and thermophysical)

- Training Cetim Academy Inter or tailor-made courses in forging and foundry metallurgy (50 forging/foundry courses available, including 9 dedicated to metallurgy)

Your benefits

A comprehensive offering (digital metallurgy, experimental foundry, characterisation) tailored to your needs

Time savings in development and fewer fine-tuning trials thanks to our digital approach

Direct access to a multidisciplinary team covering metallurgy, foundry and forging processes