Increase the efficiency of your tools and the relevance of your simulation results

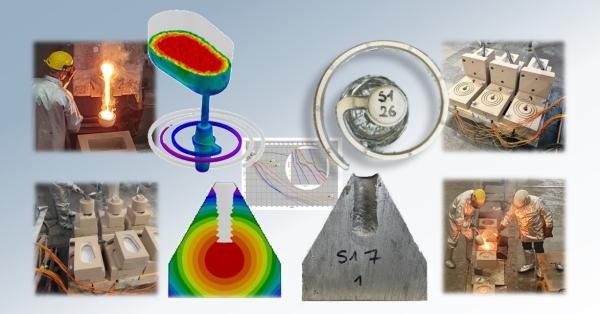

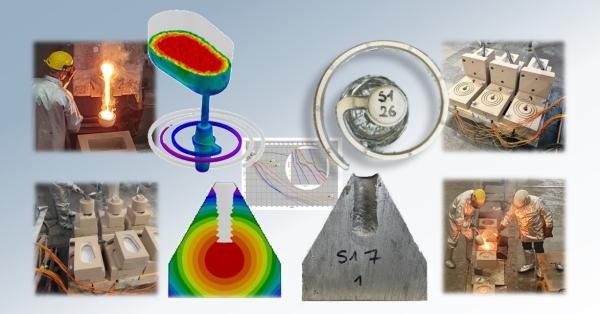

Improving the reliability of foundry process simulation

Your expectations

You are a CAD office or production methods office in the foundry industry. To achieve your product/process development requirements (quality, weight & cost reduction, addition of functions, etc.), numerical process simulation will give you a competitive lever in order to:

- Develop your parts more quickly by defining in advance your process or metallurgical parameters

- Make your feeding systems (gating, filling channels) more efficient

- Improve your process stability (reduced scrap rate that remains stable over time)

- Have more reliable input data to strengthen the numerical chain

Our solutions

In addition to our ability to perform process simulations for you, our teams can support you in various areas of reliability improvement, depending on your needs:

- The creation or consolidation of thermophysical databases specific to the materials actually used in your production workshops.

This data, based on characterisations or calculations, can then be used in digital and physical experimental designs to improve the reliability of all material characteristics (alloy, tooling/mould), adapted to your simulation software.

- The implementation of sensitivity analyses of your production tool to identify key parameters and integrate them into your simulation software in order to improve its representativeness.

Using digital and physical test plans on site, our teams carry out sensitivity analyses to identify the simulation parameters that need to be controlled in line with the specific characteristics of your production tool.

- Evaluation of innovative solutions (cluster architecture, moulding material, etc.) through digital simulation

The deployment of multi-criteria analysis based on your technical reference system allows different configurations to be tested quickly.

Your benefits

More reliable results, regardless of your simulation software, allowing you to operate with confidence.

Accelerated innovation thanks to our numerical analysis methods.

Support from multidisciplinary teams (process, metallurgy, digital) with extensive knowledge of process simulation tools and various modelling techniques.

Access to the results of R&D programmes on the thermophysical characterisation of alloys and casting materials.