Leak hunting has become a priority. As a matter of fact, the drinking water distribution networks in service in France exhibit more than 20% losses due to leaks. For Veolia which designs, installs, operates and maintains a part of these networks, the use of pipes and connection pieces likely to jeopardise the reliability of installations is out of the question. Therefore, Veolia has decided to impose a specific leak tightness qualification on its suppliers. So that they can be validated, the connection pieces must withstand water pressure cycling tests performed at ambient temperature. “These tests used to be performed by one of our subsidiaries but, as they are now used to validate products under development with some of our other suppliers, we had to find an external service provider. This was a question of confidentiality. As a result, we decided to call on Cetim, their teams are quick to react and adapt to our requirements”, declares Veolia technical management. In addition to validation, these tests are also used to classify the parts according to their performance levels.

100,000 cycles and different pressures

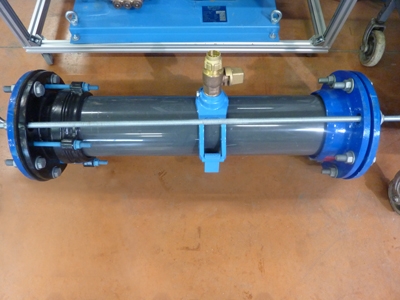

The tests concern connection fittings for cast iron, PVC and polyethylene pipes. For PEHD and PVC items, the connection fittings are fixed systems whose diameter corresponds to the diameter of the pipe. For cast iron items, the diameter of the fittings adapts to the diameter of the pipe. Cetim receives the parts already assembled and bench-tests them at different pressures. 100,000 cycles, distributed in several pressures ranges between 16 and 30 bars, are performed. Each test takes approximately one month, including shutdown periods for pressure adjustment. To date, nine piping pieces were tested with their connection systems, with others to come. Veolia removed from its references, without hesitation, all the products which did not withstand this validation test.