As part of one of its R&D projects, TotalEnergies has designed a very unusual turbine. “This turbine was designed with a view to equipping a robot used for the inspection of pipelines under pressure. To carry out its tasks, the robot must therefore be able to generate its own power autonomously”, explains François-Xavier Pasquet, development engineer working in the Deep Offshore program at the R&D department of TotalEnergies. The goal was to determine whether the turbine was able to produce a sufficient amount of energy to power the robot under different conditions of single-phase or multiphase flow, and TotalEnergies asked Cetim for support.

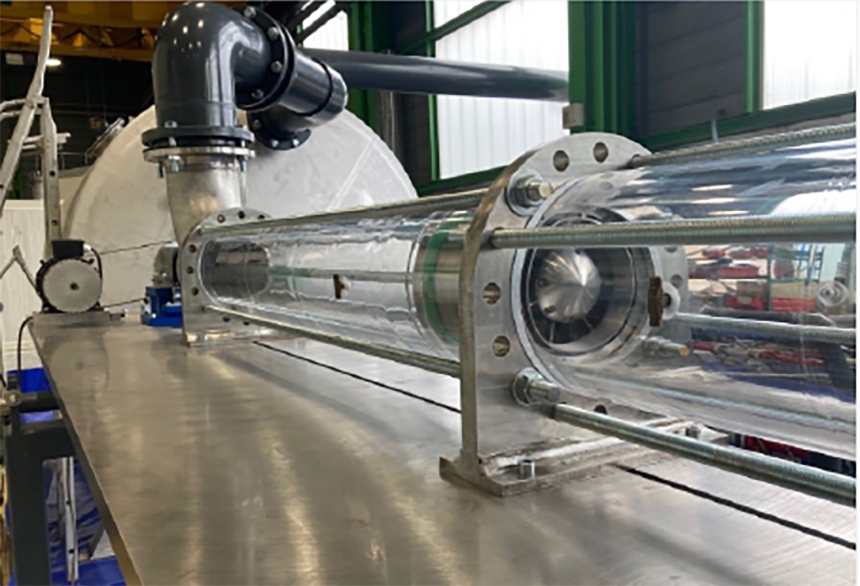

Further to the manufacture of the turbine, which has a diameter of 200 mm, Cetim designed a specific test bench able to reproduce an environment that is as similar to the real operating environment as possible. “We used a mixture of air, water and oil. The test bench had to be able to continuously generate a great variety of flows from these three phases”, explains Alexandre Cenet, mechanical engineer at Cetim.

Testing at various flow regimes

To make the experiment visible, long clear pipes made of polymethyl methacrylate (PMMA) were used. A tank used as a phase separator also allowed the system to run continuously. In practice, the fluids were sent to the turbine at different flow rates and regimes. As a matter of fact, the predominance of the liquid or gas phase completely changes the shape of the flow in the test pipe. Therefore, the objective was to control and reproduce all the flow regimes (wavy, stratified, slug, plug) which can be present in a mixture of water, gas and oil. The extremely variable power generated by the turbine was then measured and analysed for each scenario.

The tests allowed TotalEnergies to prove the relevance of their device and Cetim to successfully meet the specific and complex requirements relating to the inspection of the inside of pipes without interrupting the flow (export, production, transfer of fluids).