With its knowledge in terms of radioactive material packaging, transport and storage systems, TN International, a wholly‑owned subsidiary of the Areva group, has been a significant stakeholder in the nuclear industry for more than 40 years. These radioactive materials (uranium ore, new or used fuels) are contained in fully sealed large-sized packaging containers designed to protect the environment against the radioactive elements they contain (gases, powders, liquids, etc.). The plugs and lids of these containers are sealed with an elastomer O-ring seal compressed in a groove. The resistance of this seal must be experimentally demonstrated for a set of events corresponding to the mandatory tests in normal (CNT) and accidental (CAT) transport conditions.

Tightness tests

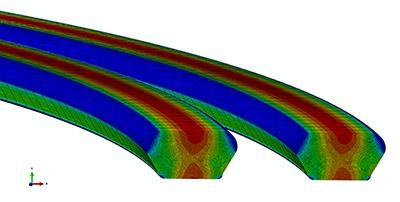

Cetim teams have performed test campaigns on the seals in order to test their gas tightness and their resistance to extreme temperatures (from -40 °C to +250 °C in accidental transport conditions). The leakage flow is therefore measured on a daily basis until an interface leak is obtained. Then, a seal ageing law is deduced. Since 2012, Cetim has also been performing modelling work on behalf of TN International for various sealing systems. In particular, these analyses concern the deformation of the compressed seal in its groove and the forces between the seal and the groove depending on the filling rate of the groove and the rate of compression of the seal. Then, the best systems stemming from these studies are qualified.