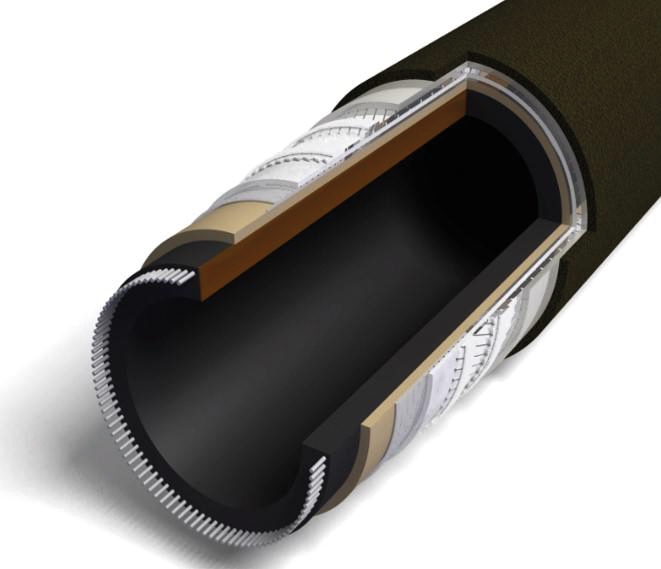

Huge quantities of ores (copper, zinc, lead, etc.) of hydrothermal origin lie at depths between 1,000 and 2,000 meters, close to oceanic ridges, where tectonic plates touch each other. Significant research work is being performed on the exploitation of these ore deposits, especially within the Fonasurf consortium led by Technip and its partners, DCNS and Comex. “In addition to the coordination of the consortium, Technip is also in charge of developing flexible pipes for the transfer of crushed ore from submarine facilities to the surface”, says Johann Rongau, project manager with Technip.

Characterising wear

In order to solve the wear problems related to ore particles, Technip’s engineers designed different types of tubes and tested them in a test loop in the United States. The characterisation of the wear of the tubes was entrusted to Cetim’s experts. Johann Rongau explains : “We have been working with Cetim on this project for several years. As a matter of fact, Cetim has top-class technical skills and resources to analyse the damage of the tubes and propose economically viable solutions”. Macroscopic and microscopic analyses of the damage were carried out on approximately twenty samples. The quantification of the wear levels and the understanding of the damage process allowed Technip to select the best solution, both technically and economically. This research work on flexible pipes was funded by Bpifrance and won Phases 1 and 2 of the worldwide innovation challenge (Innovation 2030). And Johann Rongau to conclude : “We are now focusing on the industrial production of the selected solution before its release on the market, through the manufacturing of a prototype of flexible pipe”.