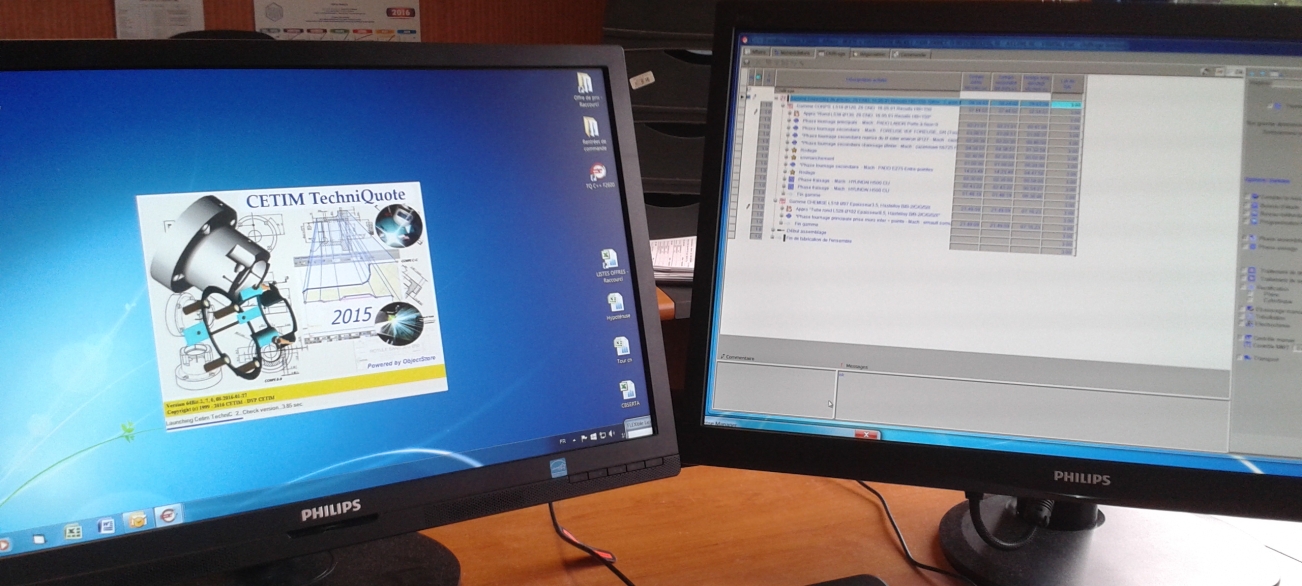

Accurately determining the manufacturing costs of parts in order to establish a quote, which meets the expectations of customers and matches market prices, is essential to ensure the long-term survival of a company. At Serta France, Marc Manière, Chairman of this company specialised in the production of mechanical parts for third parties, was previously in charge of costing. He decided to entrust this delicate mission to one of his experienced technicians, and decided to switch to a digital process at the same time. After investigating the options, Marc Manière opted for the TechniQuote software application developed by Cetim. Once the material and quantity of parts to be manufactured have been selected, the software automatically establishes the detailed costing for the part or the series to be manufactured based on its 3D CAD model or a printed drawing. The application also determines the manufacturing process and highlights machining costs and times.

More details

"For a certain period, we produced quotes manually, in parallel to using the software. We soon stopped, as we realised that the results were equivalent", explained Jean‑Michel Ailleaume, who uses the software on a daily basis. Furthermore, TechniQuote benefits from a few precious advantages compared with the manual method. The software provides more details on the operations and archives manufacturing processes and material prices, to name just a few. On this basis, the data can be reused for a more rapid costing of the manufacturing of a larger number of parts or a similar part. "TechniQuote is not frozen in time. Machining processes corresponding to our production methods and resources can be created using this software. The software offers wide-ranging configuration options, ensuring that expectations can be met and are matching our company’s working methods. At the end of the day, the price matches reality, with a very small margin of error", concluded Jean-Michel Ailleaume.