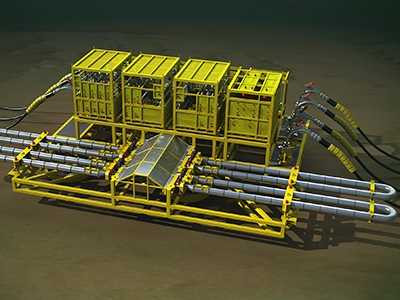

As part of the Spool- Sep project, Saipem invented a separation system intended to be used in the extraction facilities of deep offshore oil fields. This system is installed at a depth of 3,000 m and serves to separate the pumped mixture of oil, water and sand, so that only the crude oil is recovered at the topside facilities. The simple and robust solution separates the elements by making light of the pressure and decanting them in a structure composed of several horizontal pipes working in parallel.

From the mock-up to validation

Saipem commissioned Cetim to design a mock-up of its concept as a means of validating and optimising it. “We brought them our ideas. We knew exactly what we wanted to test. Cetim’s engineers designed the test bench, its instrumentation and control system, entirely in keeping with our specifications,” explained Sadia Shaiek, subsea processing project manager, at Saipem.

Besides the fluid circulation and injection equipment, a large variety of instruments were installed on the separator test bench comprised of four transparent pipes that were 20 cm in diameter and 18 metres long. These instruments were used to assess the efficiency of the separator on a mixture composed of compressed air, water and modelled coloured oil. They included temperature probes, pressure sensors as well as cameras making it possible to examine the flows and separation in real time by analysing the images. In addition two devices were used to measure the concentration of oil in the water and vice versa at separator output. As the test campaigns progressed, multiphase flow modelling tools helped to gradually optimise the separator.

Working in harmony

“The optimisation and assessment phase of the separation system took place over a span of 3 years, via tests campaigns ranging from three to six months. Saipem oversaw all the operations and the analysis of the results. However we worked closely with Cetim’s experts in order to upgrade some operating parameters based on the findings.” stated Sadia Shaiek.

The last phase of testing was carried out in conjunction with Total and Petrobras operators. Crude oil was added. Cetim implemented the necessary safety and other equipment. Now that the concept has been validated, the development phase of this innovative separator will continue out in the field in real conditions.