Approximately 300 wind turbines will soon be installed off the Channel coasts. This is the context and one of the reasons which led Otecmi to dispatch two of its employees to Cetim to receive training in infrared thermography. Otecmi is a company located near Cherbourg (France), specialising in non-destructive testing of aerospace equipment. Alain Maigrot, head of the Aerospace NDT Department at Otecmi, explains: “We wanted to better know the potential of infrared thermography, especially for the inspection of composite materials, since they are being increasingly used in various industrial sectors such as aerospace, automobile, railway, wind turbines, etc..”

Cracks, delaminations and inclusions

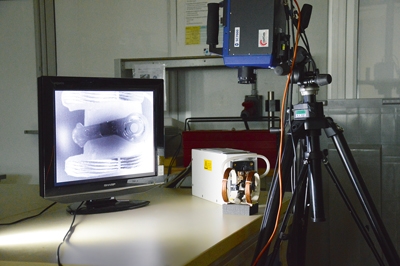

Active infrared thermography is a technique which consists in exposing the item to be inspected to a controlled external excitation and then analysing heat propagation. The detected disturbance will then reveal surface or subsurface flaws, if any, such as cracks, delaminations, corrosion, inclusions of water or foreign matters, etc.

The 2-day training provided by Cetim starts with a presentation of the physical principles of the method, the equipment used, the types of excitation, the image processing software, the parameters that have significant impact, etc.

And Alain Maigrot to conclude: “During training, we then performed many tests on various metallic, plastic and composite materials. Infrared thermography proved to be a fast and efficient technique which also allows good traceability. It has a significant potential for the inspection of composite materials and we already plan to apply it to many industrial sectors.”