NTN Transmissions Europe has met the challenge of inspecting forgings without human interpretation at a rate of 5 seconds per forging! This unprecedented feat was achieved at its Crézancy plant located in Aisne (France), where it manufactures 60% of the group’s forgings for the European market: tulips and joint housings for motor vehicle transmissions. « These forgings must be free of laps, defects caused by metal flow during the hot forging process. Currently, the inspection is carried out manually by an operator who examines each forging individually. This is a tedious task which may lead to false diagnoses. Consequently, the visual inspection must be replaced with a reliable andautomatic device », explained Antoine Selosse, Site Manager.

A multi-phase study

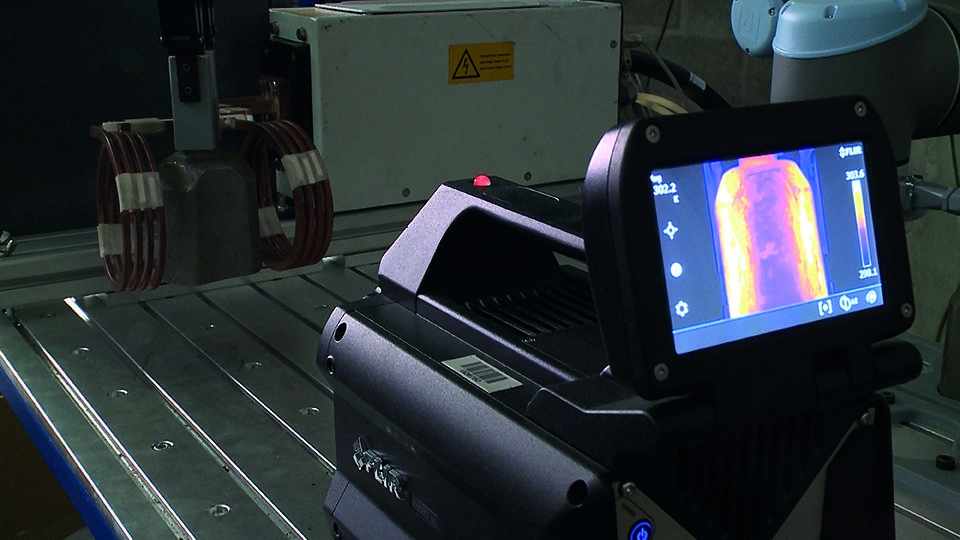

This project began with a study by Cetim’s professional forging commission, combining sector representatives, trade associations and experts from the Centre, to replace the manual inspection of parts with an automated nondestructive testing (NDT) device. They were faced with two major challenges:achieving inspection speeds that were identical to the forging speeds and using an environmentally friendly system. Cetim firstly developed a demonstrator for the active infrared thermography testing of tulips. The next step involved assessing and automating the demonstrator on the NTN site. Integration on a line « The collective work conducted by the professional commission is now complete. However I decided to adopt this testing technology in my company. We are currently working with Cetim to integrate a robotised testing station to a production line. Eventually, our four forging lines which produce the 70 tulip and joint housing references will be equipped with this system », stated Antoine Selosse.