Study by Cetim’s professional commission to replace the manuel inspection with an automated NDT device.

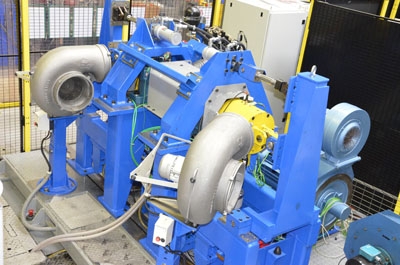

Demonstrator development.

Assessment and automatisation.

Cetim provides industrial manufacturers with support in their development of non-destructive testing devices for materials, products and equipment.