Petroleum solvent-based evaporable fluids used for part stamping have been found to be toxic for human health and the environment, as such Molydal embarked on an innovative approach to design biolubricants. Accordingly, it carried out cooperative research work with the private research centre ARD (Agro-industrie Recherches et Développements “Agro-industries, research and Development”) and Cetim.

"As part of a project approved by the industries and agro-resources competitive cluster, ARD provided us raw materials to be included in our formulas, explains Didier Fargin, technical director and quality assurance manager at Molydal. Cetim then carried out the tests which helped us to select the best products."

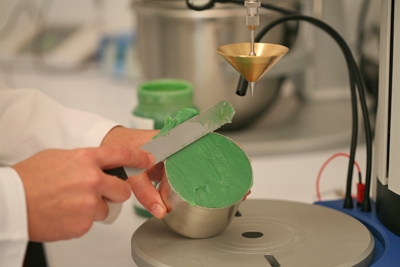

Succinic acid is found in plants and seven lubricants were created from it. Cetim characterised the quality level of these lubricants with the "four ball" test.

Two criteria were selected: extreme pressure and anti-wear. At the same time, the tribological performances were validated with a Testolub. This stamping modelling and test equipment was used to assess the ratio of the loads between the blank holder and the stamp. The lower this ratio, the more efficient the lubricant.

These laboratory tests were used to qualify the new Molydal formulations. Two were pre-selected to undergo qualification tests in the field. Furthermore, these bio-based lubricants were found to be significantly more effective than conventional ones! Lubricant consumption is reduced by 20% with the same stamping quality.

In the end, Molydal qualified and patented only one solution. This biolubricant is marketed under the Luba brand and is compatible with all types of materials. When applied, it leaves a greasy film that breaks down above 190°C without leaving any marks or charred residues on the parts.