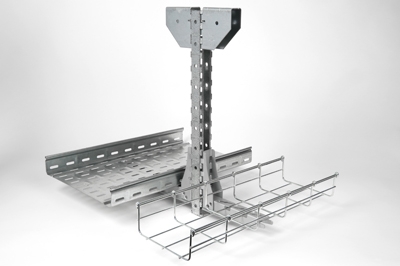

GGewiss France, based in Liernais on France’s Côte d’Or, manufactures power distribution equipment. The company was keen to have Cetim check the design of its new system for supporting cable routes. The aim was to validate the new choices in technology developed by the company’s design office. The collaboration resulted in a more reliable system that is easier to set up.

As Frédéric Barlerin, technical manager, explains, “The new system is so innovative that we have protected it by taking out two patents”.

From design to manufacture

This good report led the company to continue its ongoing collaboration and to explore new ways of optimising the manufacture of the part. The goal was to develop a single tool that would be capable of making the 46 different parts of the newly-created product in an automated manner.

No sooner said than done! And the leap in technology was substantial. All that remained was to manufacture the machine capable of making the parts automatically. “We decided to ask for help in this area too with the drawing up of the specifications and analysis of quotes”, continues Frédéric Barlerin. The results met with expectations.

“Previously, we had to change the tool for each of the different parts to be manufactured. It was a manual operation that meant that production had to be interrupted and required new machine settings before restarting”, further explains Barlerin. “The operation could take up half a day’s work. Today, the PLC that controls the press selects the correct reference from the 46 available depending on the customer’s order. And the change does not take more than two minutes.”