Adaptation of the test conditions and parameters, e.g. the rotational speed, in order to avoid certain phenomena and make sure that the behaviour of the reduced-size seal will be similar to that of the 14‑metre diameter seal.

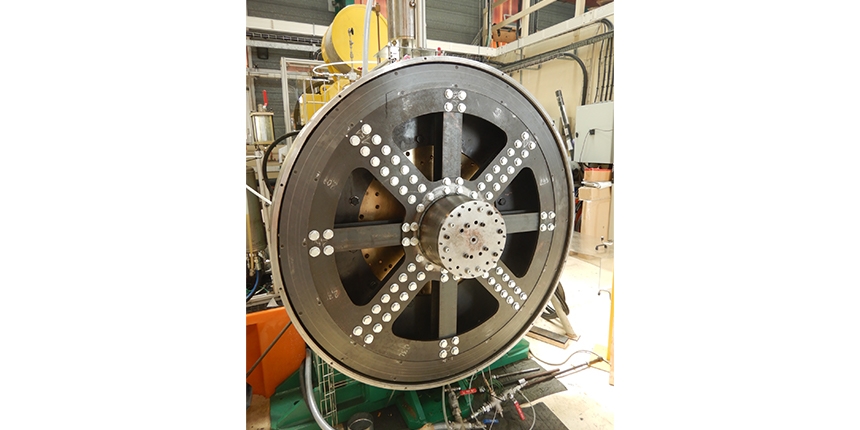

Cetim has the skills and resources to design and implement testing procedures and equipment to validate the dynamic sealing capacity of rotating seals ranging from 1 cm to 1.5 m in diameter, over a broad spectrum of temperatures (‑50°C to 200°C), speeds (50 rpm to 30,000 rpm), pressures, off-centring and vibration. Cetim can adapt the test conditions to the requirements of the application and provides an analysis of the results to assist the customer with its technical choices.