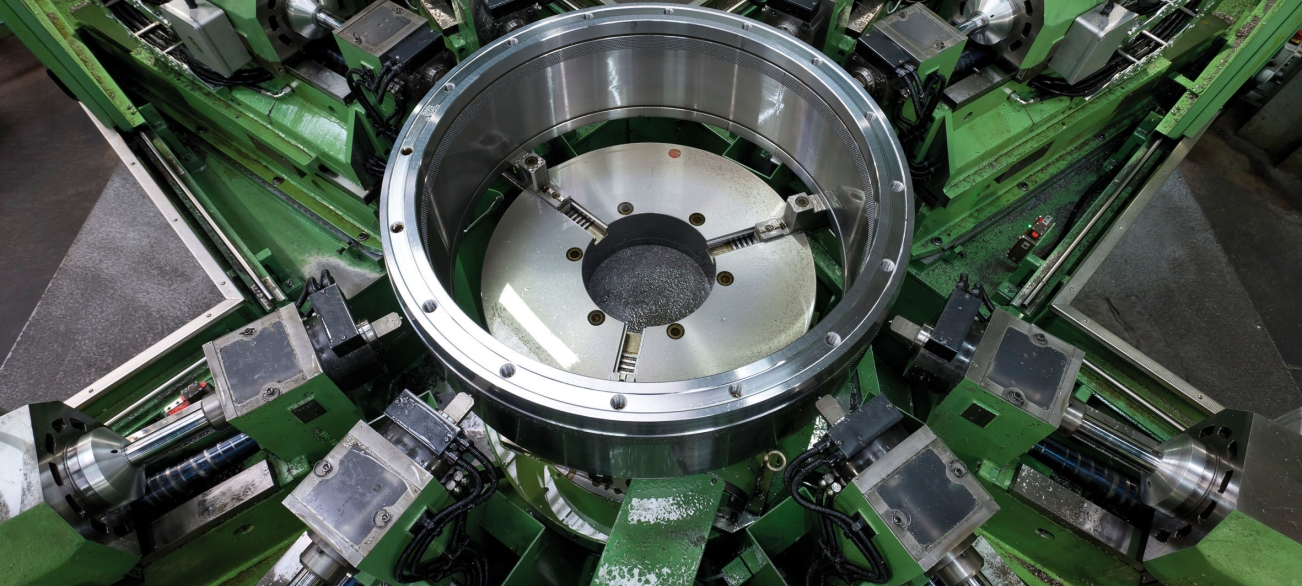

Dies are essential parts in machines which transform powder products into pellets. To optimise its manufacturing processes, Ferotec did not hesitate to call in Cetim. As Christophe Ploteau, the manager of the French manufacturer of pellet mill dies explains, “Cetim’s experts share their knowledge with us and provide technical services which complement our know-how, so we can focus on our core activity”. Ferotec relied on Cetim’s assistance again to implement its recently acquired state-of-the-art heat treatment furnace. In order to improve the reliability of its dies, Ferotec also asked Cetim to analyse the surface condition of the holes which are drilled in the dies and whose diameters and depths range from 1.2 to 30 mm and from 30 to 200 mm respectively, depending on the application.

Two studies carried out simultaneously

When the furnace was put in service, an engineer from Cetim worked on Ferotec’s site in Grand Fougeray (France) for one week. “His advice and technical assistance were invaluable to us and allowed us to optimise operating parameters such as the heating time, the cooling rate, etc.”, says Christophe Ploteau. Then, to verify the conformity of the surface conditions with the specifications, a dozen of parts and samples were analysed in laboratory after treatment in the furnace, while roughness analyses were also carried out on a few dies. This study allowed Ferotec to optimise its drilling process. And Christophe Ploteau to conclude : “We replaced some of our tools and changed the cutting angles to improve the surface condition of the holes and thus improve the quality and durability of our dies”.