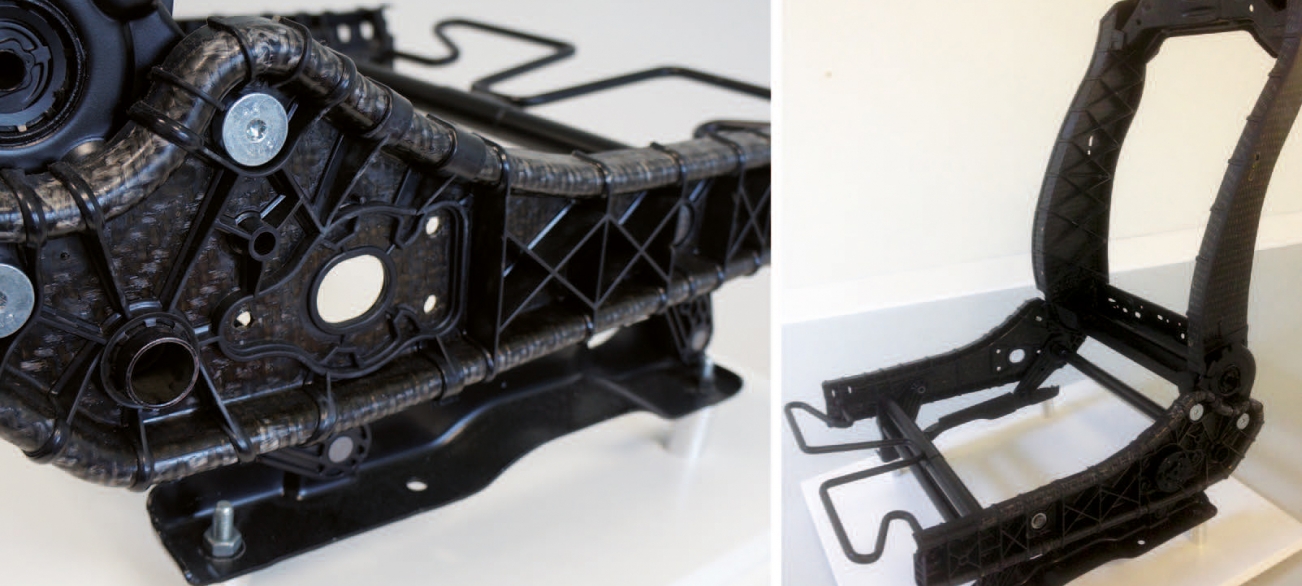

Reducing vehicle weight is now a major priority for automotive industry and one of the key means of slowing fuel consumption. Faurecia, world leader in the production of automobile seats, has fully incorporated this factor. For many years, the company has been working on the design and industrialization of light and effective composite seats. «We worked with Cetim as part of a collaborative project funded by Ademe, aiming to create a hybrid, composite cushion and backrest» explained Faurecia engineer, Fédéric Mazzamurro «This project was partially carried out on Faurecia premises, for the backrest, and partially on Cetim premises, using the high-speed QSP (Quilted Stratum Process) line recently installed and operational for seat base components. Lisi Automotive also contributed by producing composite connecting rods to be integrated in the seat».

Exemplary cooperation

Thanks to the skills and expertise gained by Cetim and Faurecia, they were able to simulate, develop and industrialise this type of product comprising primarily aluminium, steel and polyamide thermoplastic resin. The part geometry needed to be revised, and technical solutions created from the design phase for this project, to ensure a successful industrialization at the next stage. The stamping technology was then developed and the necessary tools were produced. Partners then created around a hundred prototypes in order to industrialise the process and meet the high turnover levels of the automobile industry. «We were able to learn many lessons from this project, which is now complete, and we can only be delighted with the excellent partnership with Cetim experts» concluded Frédéric Mazzamurro.