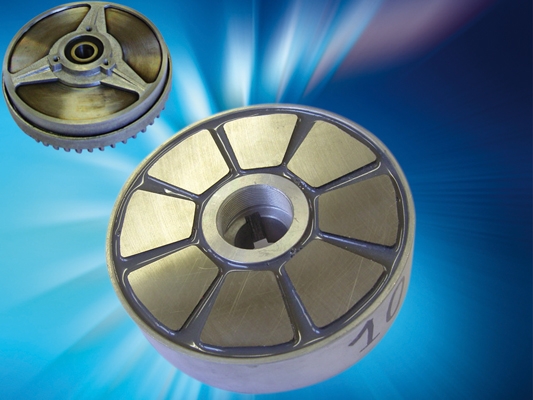

Euromag is a company located in Saint- Pierre d’Allevard in Isère (France), a city with a rich mining history and the birthplace of magnetism. Euromag manufactures aluminium, nickel and cobalt (AlNiCo)-based permanent magnets. The alloy is cast in the Croning sand moulds representing the shape of the magnet to be obtained. A heat treatment under an intense magnetic field then grants the product its magnetic properties. Finally, the magnet is given its permanent shape through grinding. “Our magnets are used in many industrial sectors (aeronautics, machine tools, etc.) as well as in the plastic injection or advertising sectors, explained Grégory Masin, Method and Quality Manager at Euromag. To better control the quality of our products output from the foundry, while saving analysis costs and time, we decided to analyse our parts by plasma torch spectrometry.”

Sensitive calibration

“As the first analyses carried out with this new technology led to different results than those usually obtained by X-ray fluorescence spectrometry, we decided to commission Cetim to establish a third method to allow us to check the various results obtained and properly calibrate a new machine”, added Grégory Masin. Consequently, the experts at Cetim specially developed a scientific approach by plasma emission spectrometry for this very particular type of material. “By comparing the results obtained with these three analysis methods, we were able to more accurately calibrate our new machine”, explained Grégory Masin. The plasma torch spectrometer should be operational in the very near future.