The operator’s hand will no longer have to bear the reaction torque at the end of the clamping operation. The latest generation screw drivers of the Desoutter Industrial Tools E-Pulse offer enhanced user comfort. As the first fully electrical tools on the market, they use a pulse mechanism which has been patented by the manufacturer. The crimping which can be programmed based on various installation strategies is no longer carried out continuously but by jolts similarly to an impact wrench. However, this innovative process subjects the electrical connector of the tool to greater vibrations. It is therefore essential to adapt the connector wire crimping of the 25 contacts reserved for power supply of the screw driver and data transmission to these new stresses.

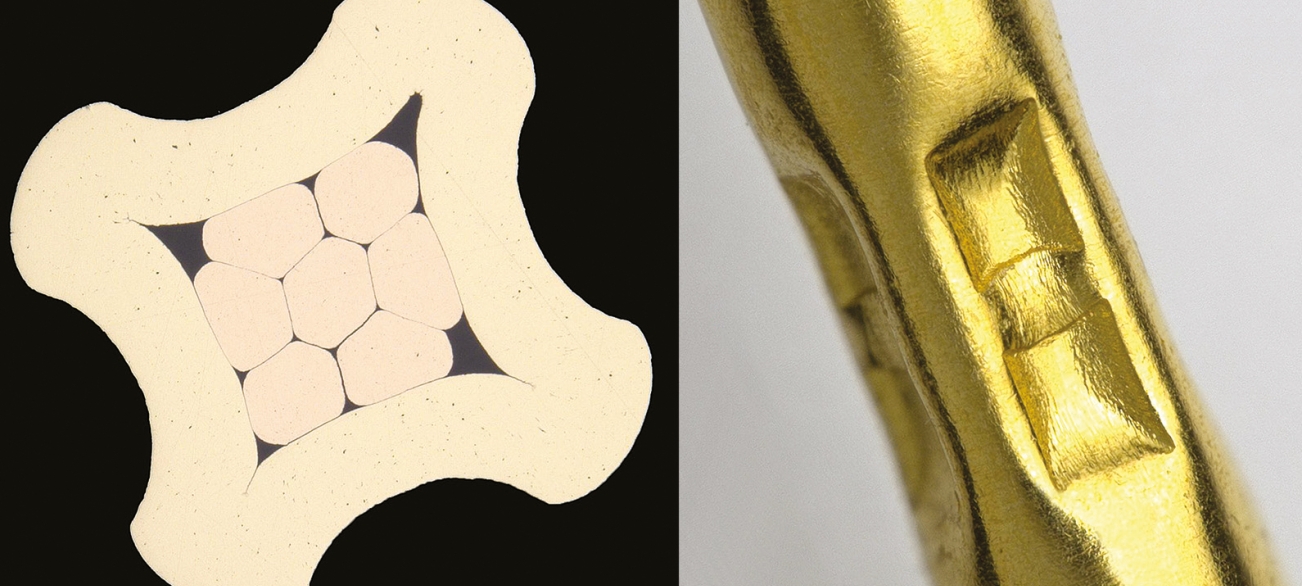

Micrographic sections

Desoutter Industrial Tools commissioned Cetim to perform a thorough analysis of the copper wire crimping. A dozen cables, crimped according to various tool settings, were entrusted to the centre. Micrographic sections of these cables of barely 1 mm in diameter were made in order to be analysed with a digital microscope. This made it possible to view and accurately measure the distribution of the copper strands in the crimping barrel. These measurements revealed that the filling rate ranged between 88% and 100%. “The images provided by the digital microscope were very explicit. We were able to note that in certain configurations, sound copper strands were damaged whereas in others, the filling rate in the crimping barrel was inadequate”, stated Eric Bretagne, Manager of product industrialisation project at Desoutter Industrial Tools. In view of these results, the industrial manufacturer determined with its connector supplier the optimum crimping parameters in order to enhance the reliability and quality of its range of E-Pulse screw drivers.