The reactor vessel heads have to be lifted during maintenance operations of the nuclear reactors. As a result, personnel have to be protected during this time against radiation and objects must be prevented from falling in the reactor core. Accordingly, Westinghouse designed a special vessel head that it commissioned CMI Services and Leroux & Lotz to manufacture. Furthermore, these vessel heads are used during vacuumising of the primary coolant system which helps to improve reactor safety during these operations. Eventually, they must equip 24 EDF 900 MW plants (34 reactors in total).

Detect very small leaks

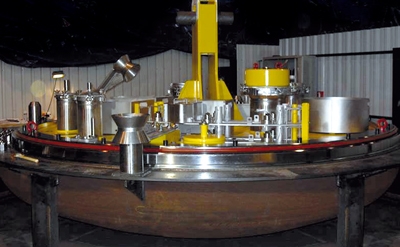

The two companies called on Cetim to perform leak-tightness tests of the vessel heads. The tests were carried out with a device simulating the reactor vessel flange seal and making it possible to qualify the finished parts. Once the special vessel head is installed, its internal face is subject to vacuum at 800 mbar above atmospheric pressure by means of a pumping unit with a 150 m3/hour capacity and an instrumented regulation system which ensures the pressure level in real time. The aim was not to raise the pressure level by more than 10 mbars per hour once the assemblies isolated.

"Cetim controls vacuum techniques and has the resources to detect leaks", explained Pierre Rogister, project manager at CMI Services. For this operation, leak was measured with a helium mass spectrometer which can quantify even the smallest leaks. Cetim therefore tested three vessel heads at CMI Services (a division of CMI SA) and four at Leroux & Lotz. The leaks detected on each occasion were within the acceptable limits.