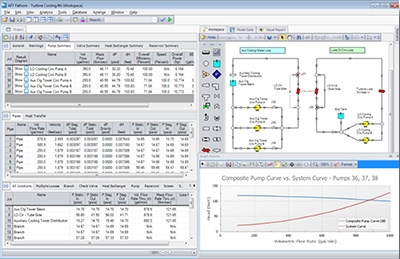

Optimising the design of a piping network so that fluids are conveyed under the operating conditions required by an industrial process is anything but easy. Besides the piping network architecture, it is also necessary to wisely select the characteristics of the pumps and control systems and to determine the operating parameters suited to the application. Defining the flow, pressure and temperature levels at the inlet and outlet of the network is not enough, it is also mandatory to know those values at all strategic points of the network. This is a complex task for any network and there is no room for approximation when hydraulically balancing the cooling system of a nuclear plant. This is a job for specialists such as Cegelec CEM, which has recognised expertise in this field and has developed, in house, specific software tools which allow it to design and optimise the operation of a cooling system. In order to standardise its engineering processes, Cegelec CEM has selected the piping network calculation and management software developed by AFT. “Our customer directed us to this software, as it is also used by some of its suppliers. Nevertheless, we examined other software solutions which could meet our needs. After a demonstration of AFT/Fathom, the software specifically developed for calculating pressure drops in incompressible fluid piping networks, we had extensive discussions with the technical support team to assess the software’s potential”, explains David Samson, Technical Manager with Cegelec CEM. The company then tested the software on a portion of the system that was being designed at the time and compared the results obtained to those given by its own calculation tools. “The results ended up showing the same trend. AFT/Fathom is easy to use and exactly meets our requirements”, states David Samson.