Thomas Drots, the manager of the calculation team of Alstom’s marine turbine energy department in Nantes (France) says, “We were already familiar with composites, but we needed more thorough knowledge on this matter”. With two of his workmates, Thomas Drots attended a three-day training session at Cetim on the dimensioning of composites parts for design (M73).

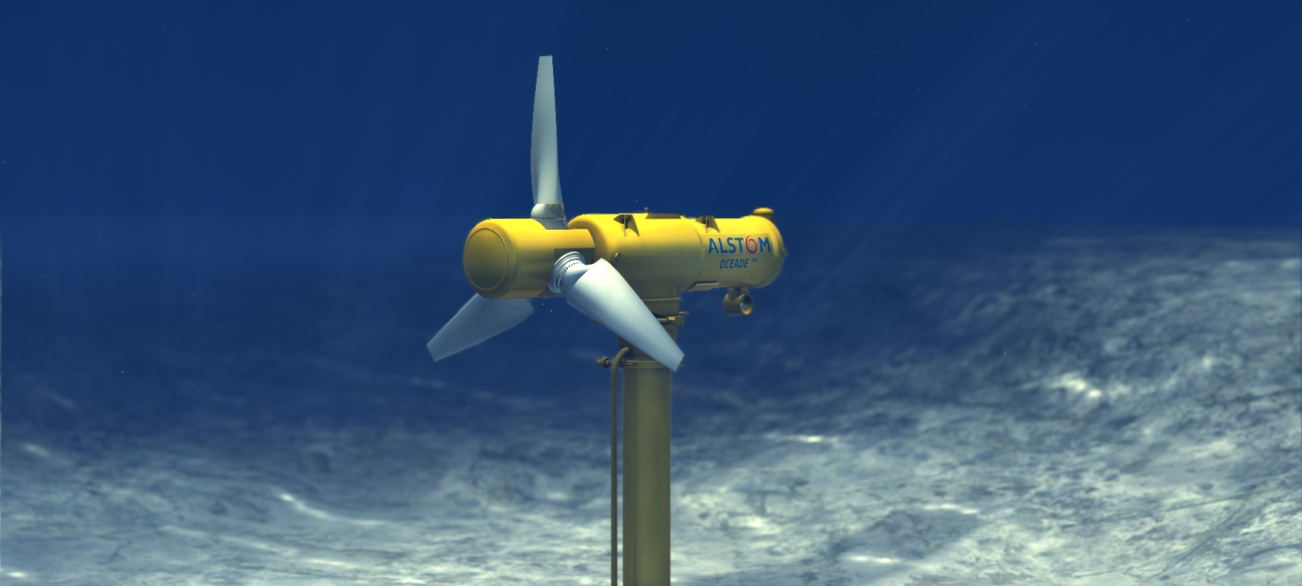

Alstom’s marine turbine energy department was created in 2009. At present, this department has more than 40 engineers and is based near Alstom’s Wind Offshore teams in Nantes in the scope of Alstom’s marine energy engineering centre.

A three-day training session

For these engineers, additional training in composites is a real advantage. Just like land wind turbine blades, marine turbine blades rely on composites. They are big, with rotors up to 18 m in diameter. A marine turbine is comprised of three blades for a total weight of approximately ten tonnes, which generates significant stresses on the motor itself. For these reasons, composites are becoming more widely used. In the future, the use of composites should extend beyond blades.

“We need to perfectly master the design and calculation of these components and we also need to have all the necessary knowledge at our disposal to better assess the proposals submitted by our suppliers of composite material components”, Thomas Drots explains.

Three days of intense training were enough to achieve the objectives.

“We reviewed everything related to composite materials and we have examined their fields of application. Then, more technical courses and exercises allowed us to refine this knowledge. Finally, we had the extremely instructive opportunity to visit a composite parts manufacturing workshop”, says Thomas Drots.