Airbus Helicopters is constantly striving for quality improvement. One such area being addressed by the helicopter manufacturer is the particle cleanliness of a number of its production parts. It has primarily focused on gearbox casings (complex parts of approximately 1 m3 in volume) and the associated components. Its aim is to substantially eliminate any pollution particles and residues. The audit of the production process combined with the various particulate pollution measurements have enabled the manufacturer to implement a plan of action and investment which significantly improves the cleanliness of the gearbox casings.

Piority actions to be taken

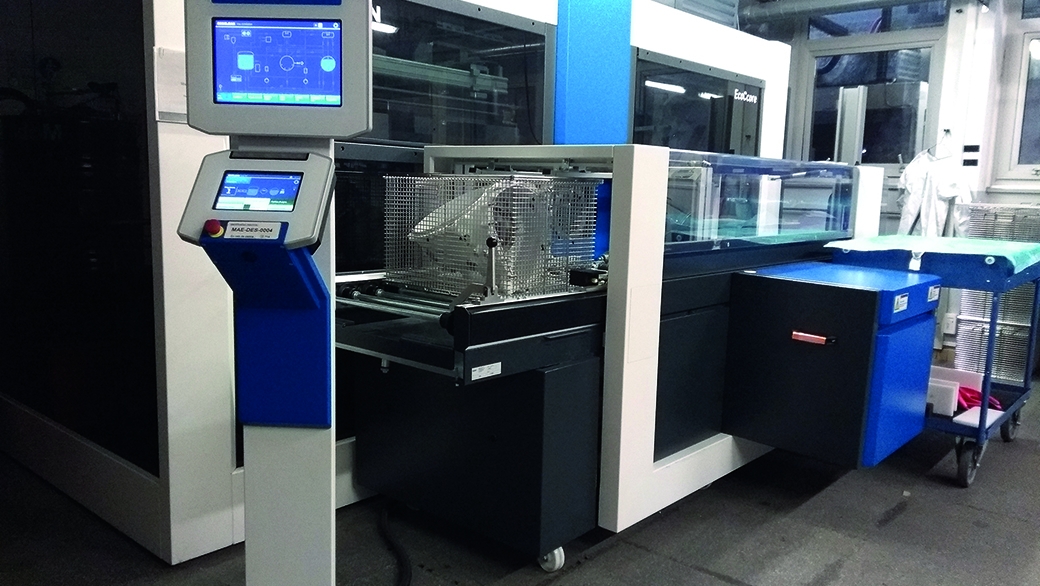

to support it in this approach, the company called on Cetim which carefully examined the various steps in the manufacturing process in order to identify the main sources of pollution. At the same time particulate pollution measurements were carried out on a number of casings by Cetim’s laboratory. Based on these measurements, the examinations conducted during the audit and the analysis of the particles trapped by the membrane filters setup at various locations in the workshops, Cetim’s experts suggested priority actions to Airbus Helicopters to be implemented in order to achieve the cleanliness goals. “We became more aware of the risks of pollution specific to the various part manufacturing steps. In addition, we learned about the existing barriers to cleanliness such as the surface treatment operations. The need for storage under appropriate conditions was also highlighted”, stated Emmanuel Colombier from the gearbox design office in charge of cleanliness at the Airbus Helicopters. It was found that compliance with certain rules and the use of appropriate operating procedures could avoid the need for a dedicated clean room for the assembly process. However, in order to guarantee the target level of cleanliness, Airbus Helicopters invested in two items of cleaning equipment one of which is capable of accommodating its large casings.