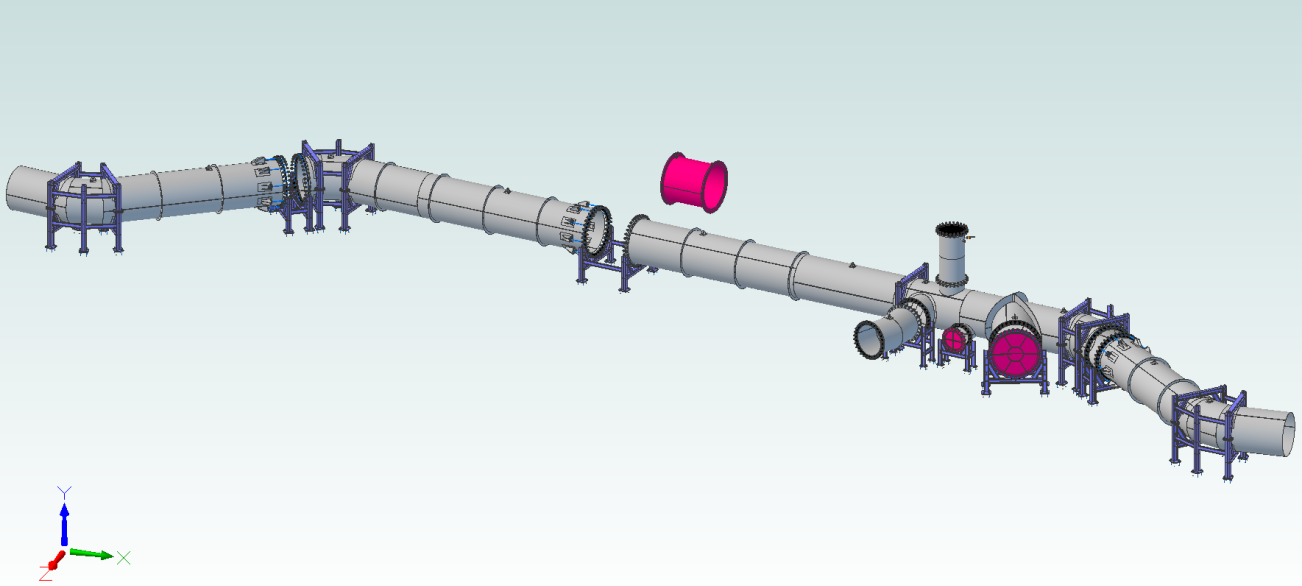

When AIMS was entrusted with building a part of the wastewater and rainwater outlet operated by the “Bassin d’Arcachon” Intermunicipal Association (Siba), everyone agreed upon the need to check the mechanical strength of this structure’s design in any situation, by digital simulation. For Sébastien Lecouleux, AIMS design office manager, “the length considered, 50 metres, was not extraordinary but the diameter, 1.40 metres, was unusual for the type of material chosen: stainless steel 316L”. How will the pipe behave in such harsh conditions as discharge from the surrounding companies, population variations (+200% to 300% in summer) and rainwater volumes affected by sudden and powerful storms? In addition to these constraints, regulations in force and French construction codes (Codeti - Industrial Piping Construction Code, and Codap - Construction Code for Unfired Pressure Vessels) have to be complied with.

Reducing pressure

“We asked Cetim to check the relevance of our design. However, should a modification to the design be required, the improvement solution had to remain within the initially planned budget”, adds Sébastien Lecouleux. After an in-depth analysis with Rohr2, the flexibility calculations revealed a few weak points regarding pipe supports, especially when the pipes are filled with water, subjected to internal pressure and unburied. In order to meet economic requirements, Cetim suggested reducing the pressure applied in the pipe during the works and before burial. As Siba accepted this solution, it was possible to keep the initial general design of the structure. The other main recommendation consisted in reinforcing connections at pipework junctions.