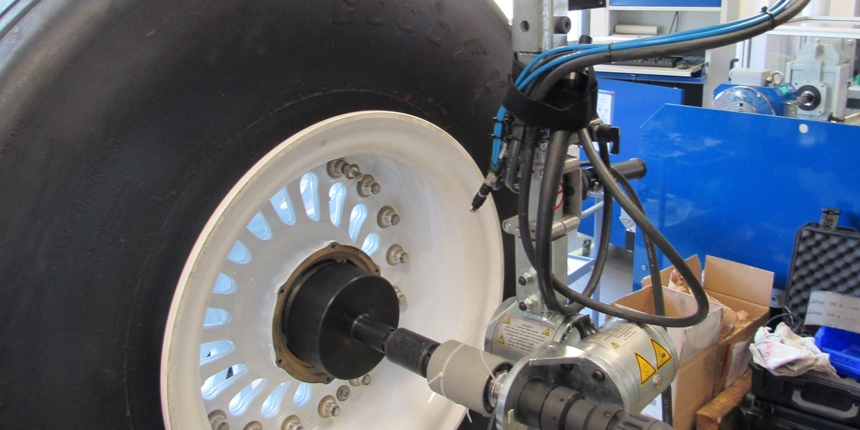

Landing gear wheels and brakes are critial components of an aircraft. Their bolted joints must comply with stringent requirements. One responsibility of Safran Landing Systems’ design office is to determine the optimum torque range to guarantee efficient performance. However, there is a gap between theory and practice that cannot be bridged without carrying out appropriate testing. This stems, on the one hand, from the fact that clamp force is obtained by applying a torque and, on the other hand, the fact that many factors impact the quality of tightening: materials, coatings or even the greases used. “We therefore entrust Cetim with the bolts, nuts, washers, grease and backing plate representative of the equipment in question (wheel or brake) to carry out tightening tests representative of real conditions”, explained Ludovic Wong, check engineer for wheels and brakes at Safran Landing Systems. These components are then installed on an instrumented test cell to determine the torque / clamp force relationship. Several tests are carried out over several batches of bolts for statistical analysis.

Confirmation by non-destructive testing

The results of these tests are confirmed by clamp force measurements on the real joint via an ultrasonic measurement process or stress gauges. The torque range to be applied (to achieve the desired clamp force) can thus be specified in the initial assembly and maintenance instructions. However, as soon as a specific characteristic of a bolted joint is altered, or if we need to use a new type of grease, then the test must be carried out again. Therefore, many tests are entrusted to Cetim on a regular basis. The results of these tests are highly valuable. A common database has been developed by Cetim to allow all entities of Safran to take advantage of these results. The designers of bolted joints can consult the database to view the results of the tests that have been performed. “This will guide our decisions, identify the issues faced by other entities and the solutions implemented”, disclosed Ludovic Wong.