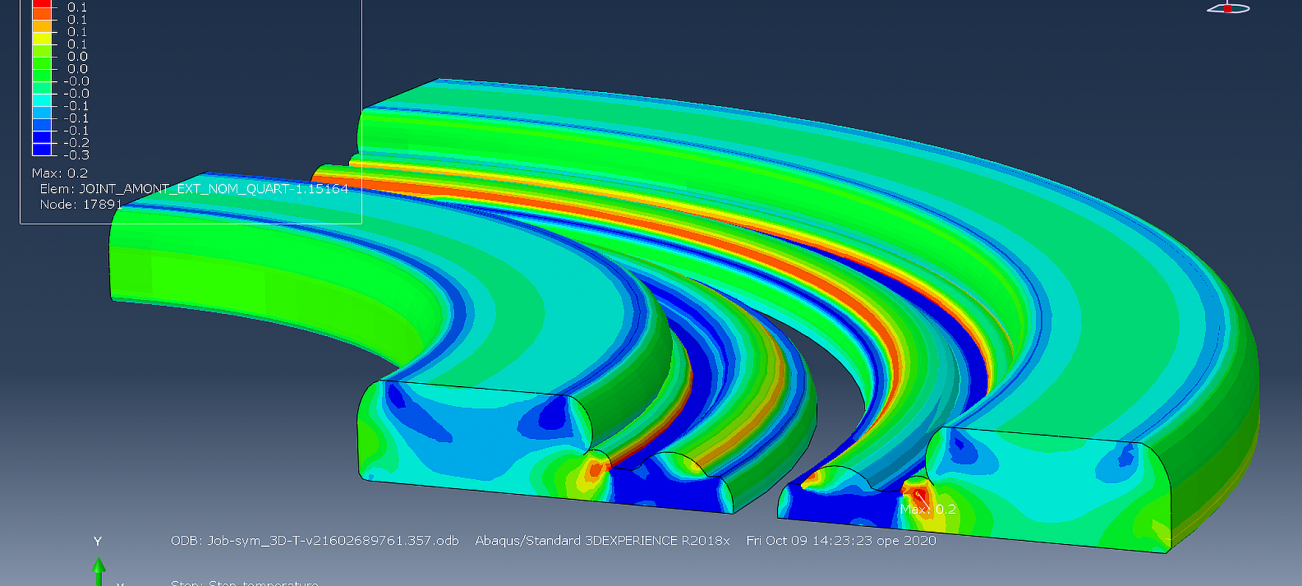

Analysing the results of tests carried out by IRSN on the model of the sealing system under normal and accidental conditions of use. Developing the numerical model representing the sealing system at scale 1, taking into account its environment. Simulating the behaviour of the gasket in various configurations by integrating representative defects.

Extensive expertise in the field of sealing which allows us to support manufacturers of all sectors, including the nuclear energy sector, in the process of validating their sealing systems. Ability to numerically model non-linear behaviours taking into account the environment, the influential parameters and representative defects.